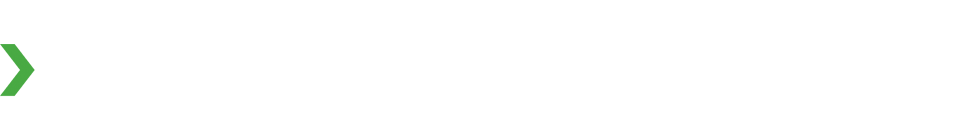

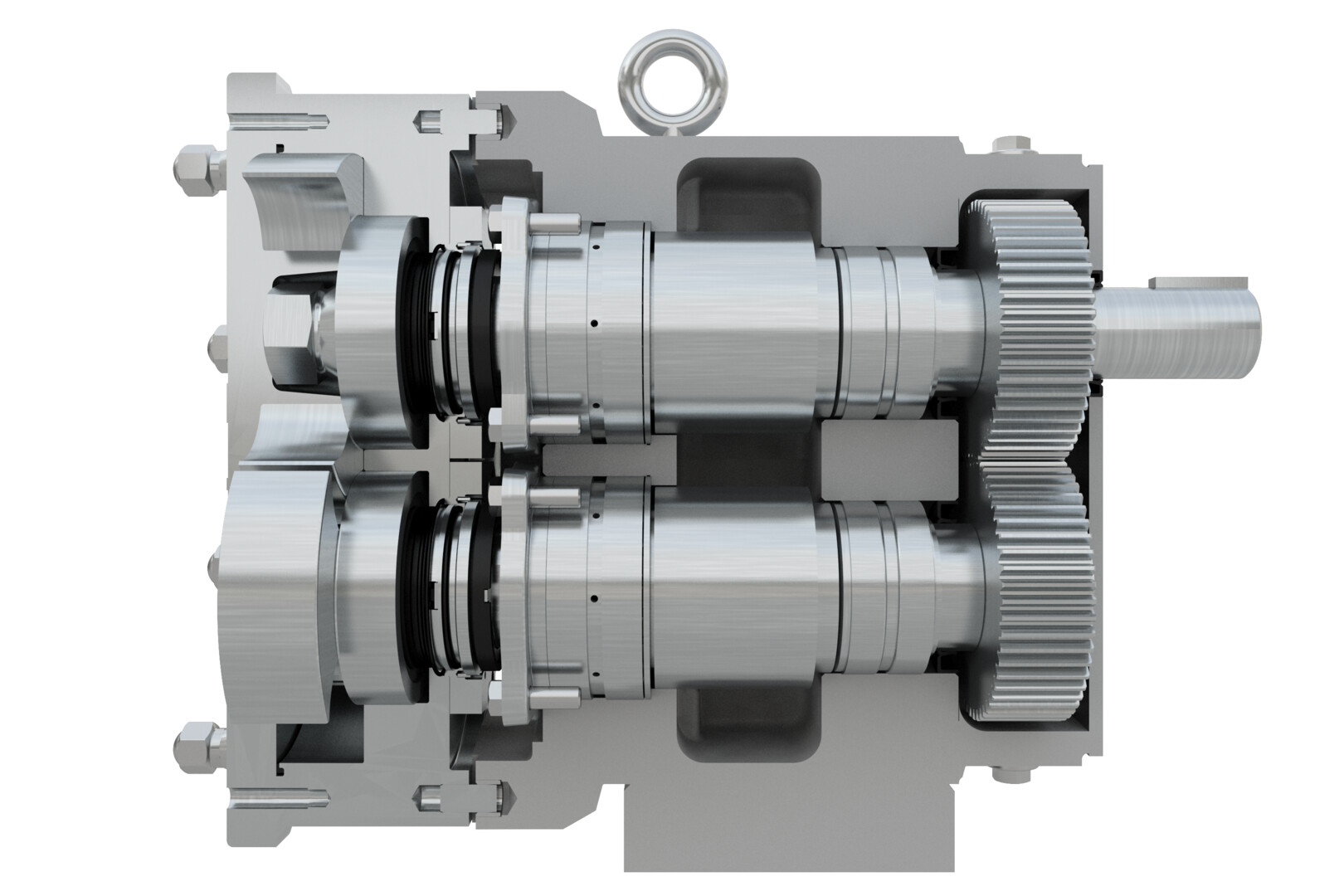

Universal 3 Series positive displacement pumps are engineered to perform in food & beverage, dairy, pharmaceutical, personal care, chemical and industrial industries. The Universal 3 series includes a standard stainless steel gear case, the choice of multiple seal options, and bearings that are sealed from the product zone. Many options are available for the Universal 3 series pump including an aseptic configuration with aseptic ports and cover.

Quick Ship Available

Ships from order date in

10 days or less.

Universal 3 Series: Hygienic Pumping Power for Food & Beverage Excellence

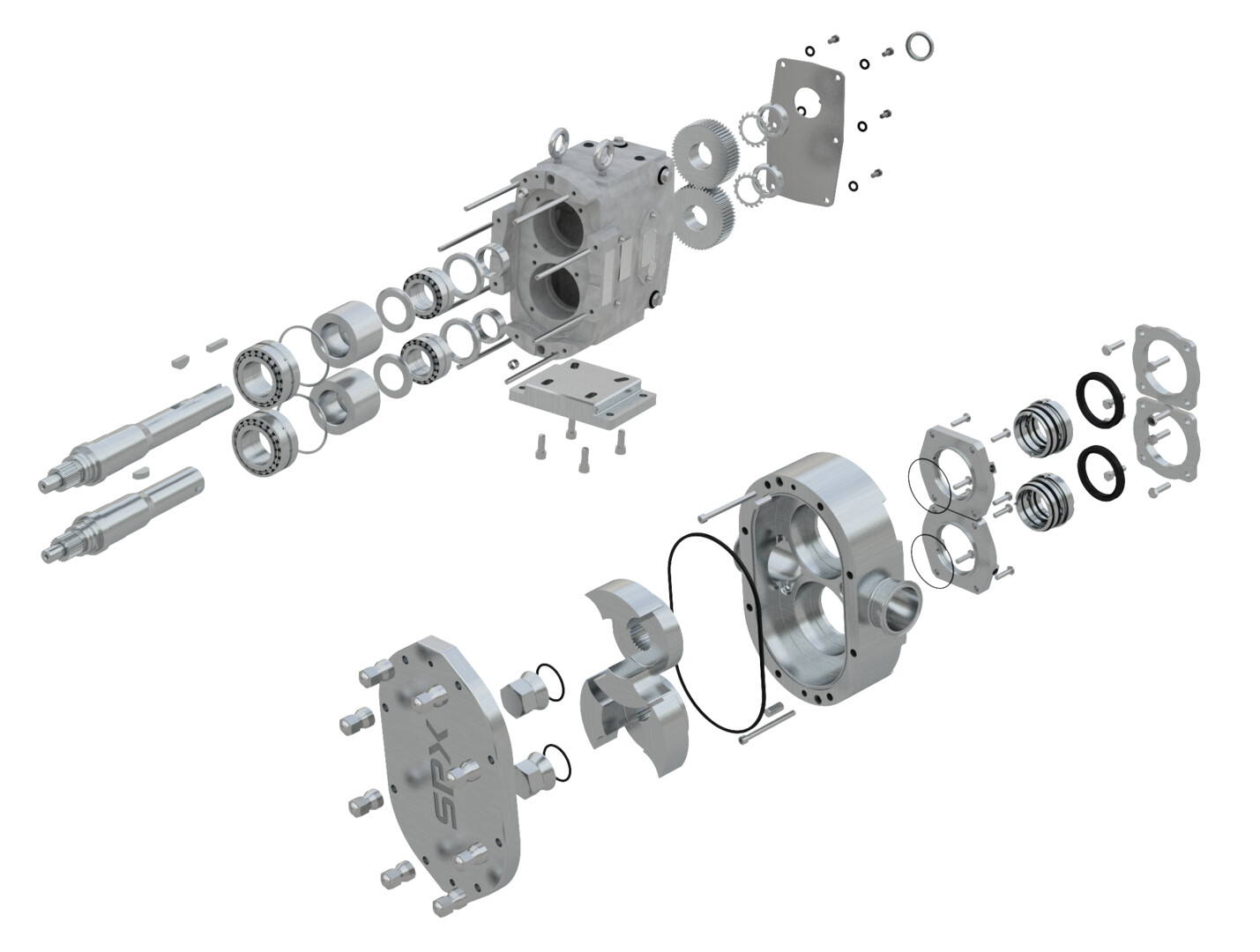

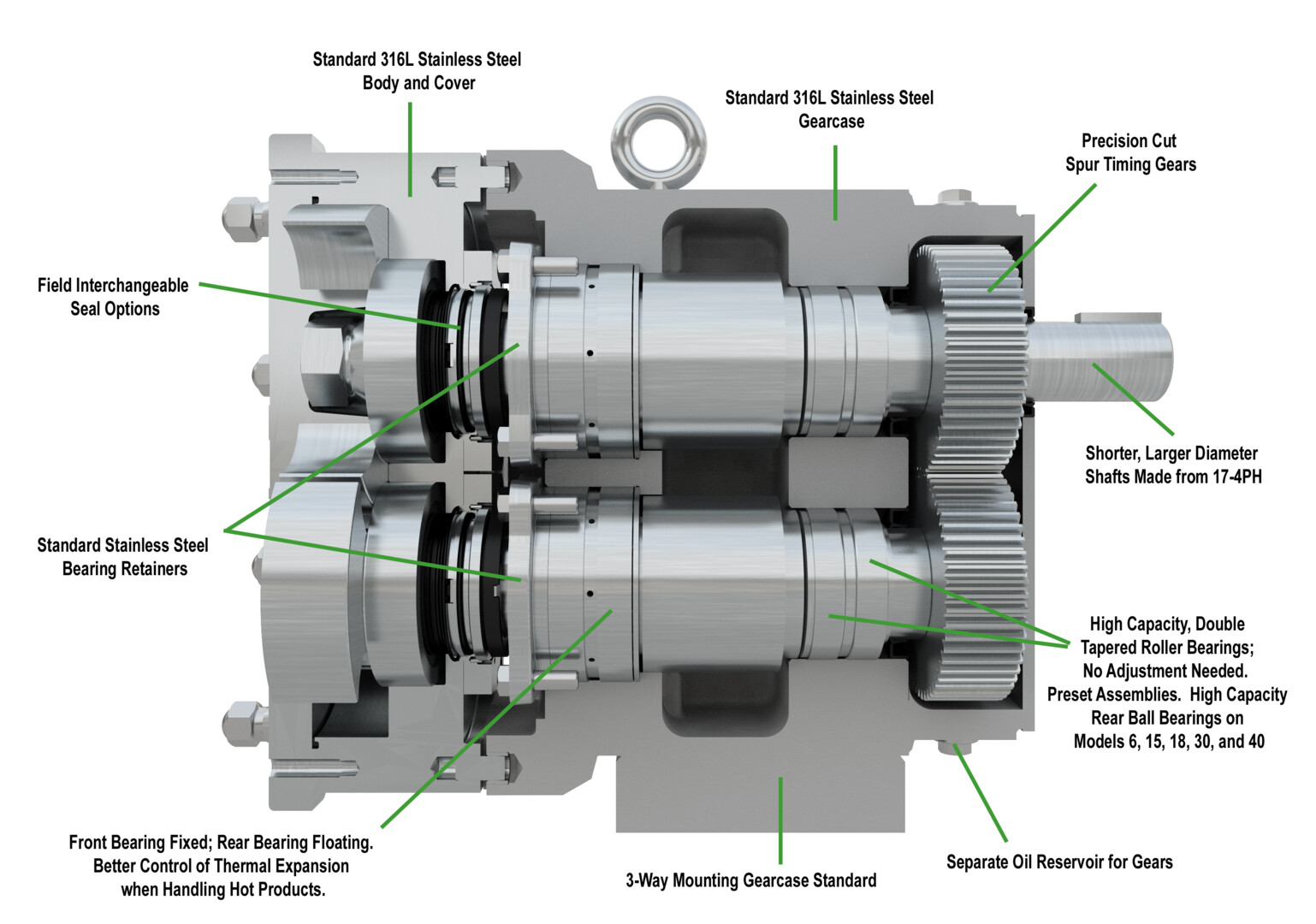

The Universal 3 Series is the latest addition to the Waukesha positive displacement pump family by SPX FLOW. Designed for hygienic applications in the food and beverage industry, it features a front-loading seal design with no bearings in the product zone. With operating pressure capacities up to 500 psi (34.5 bar) and a standard 316L stainless steel body and cover, it offers a robust and sanitary fluid transfer solution.

Assembled and tested in Delavan, WI, the pump includes "Waukesha 88" non-galling rotors and a standard 304 stainless steel gear case—engineered to withstand the rigors of daily processing environments.

Long-Life Features

- Up to 500 psi (34.5 bar) pressure capability

- Rated to 300°F (149°C) as standard

- Special rotor nut designed for extended service without loosening

- No bearings in the product zone

- Shorter, larger diameter 17-4 PH shafts:

- Reduces overhung load, improving shaft alignment and decreasing seal and bearing wear

- Improves shaft strength and stiffness to eliminate vibration

- Heavy-duty stainless steel bearing frame (standard)

- Double tapered roller bearings

- Grease-lubricated bearings for consistent lubrication across all operating conditions

- Body retaining screws maintain mechanical seal contact during inspection

- Wave spring mechanically loads the seal for extended outer seal life

- Unique mechanical seal design with 2-pin stationary seal and specially designed shaft for rotary seal

Pumps for Life™ Lifecycle Program

- Download the Pumps for Life™ Program PDF

- Buy a new U3 Pump

- Maintain with Genuine SPX FLOW Parts

- Trade in old pump for a new one at a remanufactured price

Learn more about our eXpress app pump services.

Key Applications

Food & Beverage

- Soups, Stews, Tomato Paste

- Vegetables, Dressings

- Chocolate, Fats & Oils Batters

- Cream Fillings

- Brewery, Wort

- Soft/Fruit Drinks

Dairy

- Cream, Milk

- Cheese Curd & Whey

- Cottage Cheese Yogurt

Pharmaceutical/Cosmetics

- Pill Pastes

- Hand Sanitizers

- Syrups, Extracts, Slurries

- Face Creams & Lotions

- Hair Styling Gels & Liquids

- Dyes & Alcohols

Chemical/Industrial

- Solvents, Paints

- Fuels

- Resins, Polymers & Sludges

- Oil & Lubricants

- Soaps

Our Quick Ship Program ensures rapid access to industry-leading pumps, valves, and mixer components—many shipping in as little as 5 to 10 working days.

Whether you’re responding to an urgent need or planning for maintenance, the Quick Ship Program helps keep your operations running efficiently—with reduced downtime and increased reliability. Explore product-specific details below to learn how quickly we can deliver the equipment you rely on.

Universal 3 Series Positive Displacement Pumps Quick Ship Program

Lead Time: 10 working days or less*

- Available in the most common configurations (body sizes 15–220)

- Upper/lower/side mount shaft options

- Twin Wing Alloy 88 rotors

- Single and double mechanical seals

- FKM / EPDM elastomers

- New maintenance-friendly gasket design from Nov. 2024

*Limitations apply for orders exceeding 5 units/day. Contact your sales rep for large orders or international options.

STANDARD U3 MODELS

|

MODEL |

DISPLACEMENT |

NOMINAL |

INLET/ OUTLET |

OPTIONAL INLET/ OUTLET |

PRESSURE RANGE |

MAXIMUM RPM |

APPROX SHIP WT. |

TEMP RANGE |

|---|---|---|---|---|---|---|---|---|

| 006-U3 | .0082 GAL. (.031 LITER) | 8 GPM (1.8 m3/hr.) | 1.0 in | 1.5 in | 300 PSI (20.7 bar) | 1000 | 56lb (25kg) |

Std Clearance Rotors: -40°F (-40°C) to 300° (149°C) |

| 015-U3 | .0142 GAL. (.054 LITER) | 11 GPM (2.5 m3/hr.) | 1.5 in | --- | 250 PSI (17.2 bar) | 800 | 56lb (25kg) |

|

| 018-U3 | .029 GAL. (.110 LITER) | 20 GPM (4.5 m3/hr.) | 1.5 in | 2.0 in | 200 PSI (13.8 bar) | 700 | 65lb (30kg) |

|

| 030-U3 | .060 GAL. (.227 LITER) | 36 GPM (8.2 m3/hr.) | 1.5 in | 2.0 in | 250 PSI (17.2 bar) | 600 | 130lb (59kg) |

|

| 040-U3 | .076 GAL. (.288 LITER) | 46 GPM (10.4m3/hr.) | 2.0 in | --- | 150 PSI (10.5 bar) | 600 | 140lb (64kg) |

|

| 045-U3 | .098 GAL. (.371 LITER) | 58 GPM (13.2 m3/hr.) | 2.0 in | --- | 450 PSI (31.0 bar) | 600 | 295lb (134kg) |

|

| 060-U3 | .153 GAL. (.579 LITER) | 90 GPM (20.4 m3/hr.) | 2.5 in | 3.0 in | 300 PSI (20.7 bar) | 600 | 285lb (129kg) |

|

| 130-U3 | .253 GAL. (.958 LITER) | 150 GPM (34.1 m3/hr.) | 3.0 in | --- | 200 PSI (13.8 bar) | 600 | 305lb (138kg) |

|

| 180-U3 | .380 GAL. (1.438 LITER) | 230 GPM (52.2 m3/hr.) | 3.0 in | --- | 450 PSI (31.0 bar) | 600 | 520lb (236kg) |

|

| 210-U3 | .502 GAL. (1.900 LITER) | 300 GPM (68.1 m3/hr.) | 4.0 in | --- | 500 PSI (34.5 bar) | 600 | 915lb (415kg) |

|

| 220-U3 | .521 GAL. (1.972 LITER) | 310 GPM (70.4 m3/hr.) | 4.0 in | --- | 300 PSI (20.7 bar) | 600 | 590lb (268kg) |

|

| 320-U3 | .752 GAL. (2.847 LITER) | 450 GPM (102 m3/hr.) | 6.0 in | --- | 300 PSI (20.7 bar) | 600 | 895lb (406kg) |

RECTANGULAR FLANGE U3 MODELS

|

MODEL |

DISPLACEMENT |

NOMINAL |

INLET/ W X L |

OUTLET |

PRESSURE RANGE |

MAXIMUM RPM |

APPROX SHIP WT. |

TEMP RANGE |

|---|---|---|---|---|---|---|---|---|

| 014-U3 | .0142 GAL. (.054 LITER) | 5.68 GPM (1.3 m3/hr.) | 1.44 x 4.94 | 1½" | 250 PSI (17.2 bar) | 400 | 62LB (28KG) | Std Clearance Rotors: -40°F (-40°C) to 300° (149°C) |

| 034-U3 | .060 GAL. (.227 LITER) | 24 GPM (5.5 m3/hr.) | 1.81 x 6.84 | 2" | 250 PSI (17.2 bar) | 400 | 116LB (53KG) | |

| 064-U3 | .153 GAL. (.579 LITER) | 61 GPM (13.9 m3/hr.) | 2.44 x 9.0 | 2½" | 300 PSI (20.7 bar) | 400 | 292LB (132KG) | |

| 134-U3 | .253 GAL. (.958 LITER) | 101 GPM (22.9 m3/hr.) | 3.19 x 9.38 | 3" | 200 PSI (13.8 bar) | 400 | 312LB (142KG) | |

| 184-U3 | .380 GAL. (1.483 LITER) | 152 GPM (34.5 m3/hr.) | 3.28 x 11.25 | 3" | 450 PSI (31.0 bar) | 400 | 518LB (235KG) | |

| 214-U3 | .502 GAL. (1.90 LITER) | 200 GPM (45.4 m3/hr.) | 3.45 x 12.70 | 4" | 500 PSI (34.5 bar) | 400 | 754LB (342KG) | |

| 224-U3 | .521 GAL. (1.972 LITER) | 208 GPM (47.2 m3/hr.) | 4.06 x 11.25 | 4" | 300 PSI (20.7 bar) | 400 | 559LB (254KG) | |

| 324-U3 | .752 GAL. (2.847 LITER) | 300 GPM (68.1 m3/hr.) | 4.25 x 12.70 | 6" | 300 PSI (20.7 bar) | 400 | 833LB (378KG) |

* Contact application engineering for higher pressure or higher temperature applications.

006-U3

0-1000 RPM speed range. 1" (25 mm) inlet/outlet and 1.5" (38 mm) optional inlet/outlet; suitable to 300 PSI (20.7 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| R* | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CP | I | L | O | PORT SIZE | U +.000-.001 | 2X | U3 | U1/U2 | DIFF. BETWEEN U3 AND U1/U2 "R" DIM. |

|

| IN |

12.42

|

7.61 |

10.04

|

4.21

|

1.00

|

0.88

|

6.97 |

3.23

|

2.79 | 0.40 |

| MM |

315

|

193

|

255

|

107

|

---

|

22

|

177 |

82

|

71 | 11 |

*"R" dimension shown for customers converting from a U1/U2 pump to a U3 pump. All other dimensions are the same between U1/U2/U3.

NOTE: Dimension "2X" applies for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320-U3)

NOTE: Dimensions are for guidance purposes only. Contact your SPX FLOW Representative if more detailed measurements are needed.

Approximate shipping weight without motor or base 60 lb. (27 kg.)

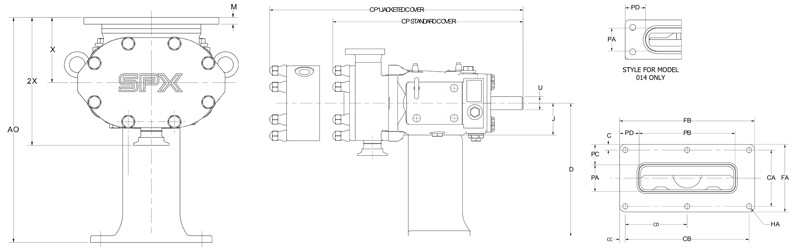

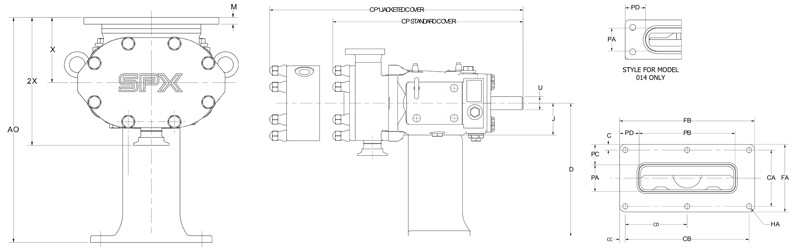

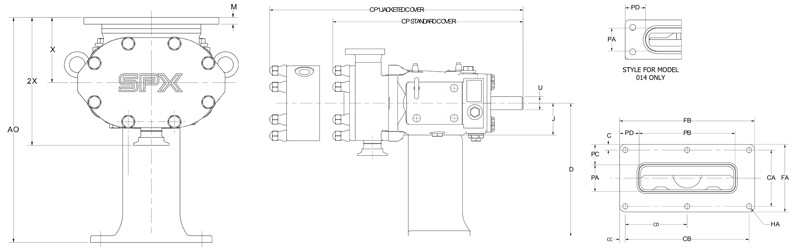

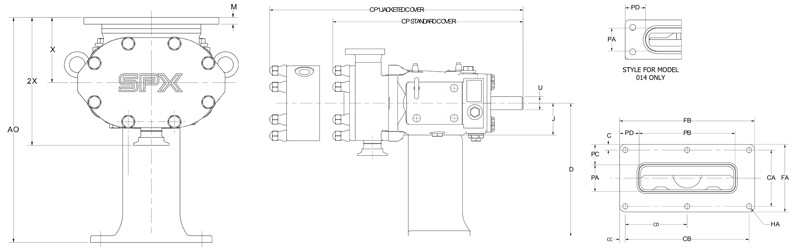

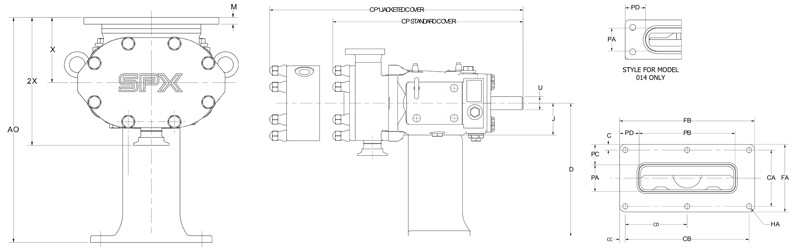

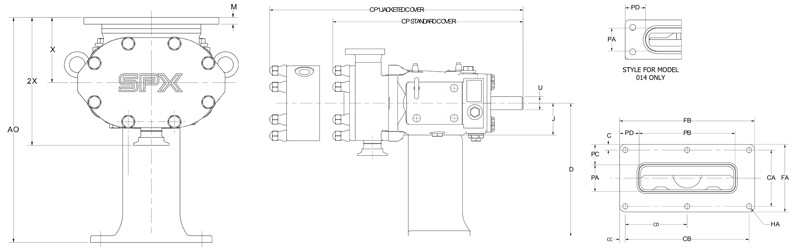

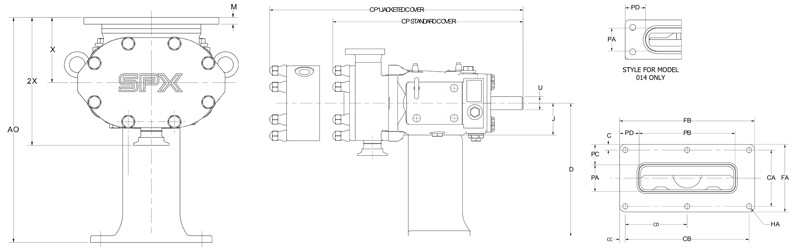

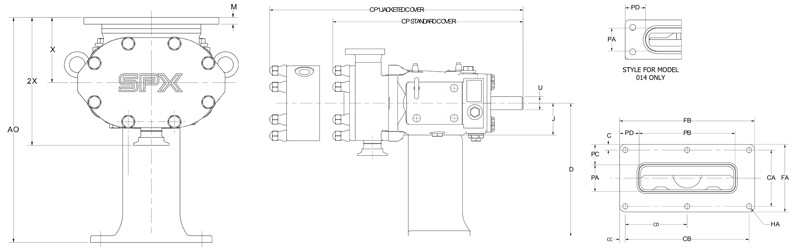

014-U3 Rectangular Flange

0-400 RPM speed range. INLET: 1.44" x 4.94" OUTLET: 1½"; suitable to 250 PSI (17.2 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| AO | C | CA | CB | CC | CD | CP1 | FA | FB | HA | M | PA | PB | PC | PD | C | 2X | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 12.5 | 0.5 | 1.63 | 0.5 | 6.5 | NA | 14.51 | 2.63 | 7.5 | 0.41 | 0.38 | 1.53 | 4.77 | 0.55 | 1.37 | 3.63 | 7.11 |

| MM | 318 | 13 | 41 | 13 | 165 | NA | 369 | 67 | 191 | 10 | 10 | 39 | 121 | 14 | 35 | 92 | 181 |

Approximate shipping weight without motor or base 62 lb. (28 kg.)

015-U3

0-800 RPM speed range. 1.5" (38 mm) inlet/outlet; suitable to 250 PSI (17.2 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| R* | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CP | I | L | O | PORT SIZE | U +.000-.001 | 2X | U3 | U1/U2 | DIFF. BETWEEN U3 AND U1/U2 "R" DIM. |

|

| IN |

12.69

|

7.61 |

10.04

|

4.21

|

1.50

|

0.88

|

6.97 |

3.23

|

2.79 | 0.40 |

| MM |

322

|

193

|

255

|

107

|

---

|

22

|

177 |

82

|

71 | 11 |

*"R" dimension shown for customers converting from a U1/U2 pump to a U3 pump. All other dimensions are the same between U1/U2/U3.

NOTE: Dimension "2X" applies for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320-U3)

NOTE: Dimensions are for guidance purposes only. Contact your SPX FLOW Representative if more detailed measurements are needed.

Approximate shipping weight without motor or base 62 lb. (28 kg.)

018-U3

0-700 RPM speed range. 1.5" (38 mm) inlet/outlet; and 2.0" (64 mm) optional inlet/outlet; suitable to 200 PSI (13.8 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| R* | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CP | I | L | O | PORT SIZE | U +.000-.001 | 2X | U3 | U1/U2 | DIFF. BETWEEN U3 AND U1/U2 "R" DIM. |

|

| IN |

13.35

|

7.61 |

10.28

|

4.21

|

1.50

|

0.88

|

7.09 |

3.47

|

3.02 | 0.50 |

| MM |

339

|

193

|

261

|

107

|

---

|

22

|

180 |

88

|

77 | 11.1 |

*"R" dimension shown for customers converting from a U1/U2 pump to a U3 pump. All other dimensions are the same between U1/U2/U3.

NOTE: Dimension "2X" applies for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320-U3)

NOTE: Dimensions are for guidance purposes only. Contact your SPX FLOW Representative if more detailed measurements are needed.

Approximate shipping weight without motor or base 65 lb. (29 kg.)

030-U3

0-600 RPM speed range. 1.5" (38 mm) inlet/outlet; and 2.0" (64 mm) optional inlet/outlet; suitable to 250 PSI (17.2 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| R* | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CP | I | L | O | PORT SIZE | U +.000-.001 | 2X | U3 | U1/U2 | DIFF. BETWEEN U3 AND U1/U2 "R" DIM. |

|

| IN |

15.16

|

8.80 |

12.05

|

5.21

|

1.50

|

1.25

|

8.50 |

4.26

|

3.84 | 0.40 |

| MM |

385

|

224

|

306

|

132

|

---

|

32

|

216 |

108

|

98 | 10.2 |

*"R" dimension shown for customers converting from a U1/U2 pump to a U3 pump. All other dimensions are the same between U1/U2/U3.

NOTE: Dimension "2X" applies for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320-U3)

NOTE: Dimensions are for guidance purposes only. Contact your SPX FLOW Representative if more detailed measurements are needed.

Approximate shipping weight without motor or base 114 lb. (52 kg.)

034-U3 Rectangular Flange

0-400 RPM speed range. INLET: 1.81" x 6.84" OUTLET: 2"; suitable to 250 PSI (17.2 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| AO | C | CA | CB | CC | CD | CP1 | FA | FB | HA | M | PA | PB | PC | PD | C | 2X | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 12.75 | 0.56 | 1.88 | 0.63 | 10.75 | NA | 17.41 | 3 | 12 | 0.53 | 0.5 | 1.87 | 6.9 | 0.56 | 2.55 | 3.88 | 8.13 |

| MM | 324 | 14 | 48 | 16 | 273 | NA | 442 | 76 | 305 | 13 | 13 | 48 | 175 | 14 | 65 | 98 | 206 |

Approximate shipping weight without motor or base 116 lb. (53 kg.)

040-U3

0-600 RPM speed range. 2.0" (51 mm) inlet/outlet; suitable to 150 PSI (10.5 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| R* | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CP | I | L | O | PORT SIZE | U +.000-.001 | 2X | U3 | U1/U2 | DIFF. BETWEEN U3 AND U1/U2 "R" DIM. |

|

| IN |

15.54

|

8.80 |

12.21

|

5.21

|

2.00

|

1.25

|

8.64 |

4.43

|

4.00 | 0.40 |

| MM |

395

|

224

|

310

|

132

|

---

|

32

|

219 |

113

|

102 | 10.5 |

*"R" dimension shown for customers converting from a U1/U2 pump to a U3 pump. All other dimensions are the same between U1/U2/U3.

NOTE: Dimension "2X" applies for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320-U3)

NOTE: Dimensions are for guidance purposes only. Contact your SPX FLOW Representative if more detailed measurements are needed.

Approximate shipping weight without motor or base 117 lb. (53 kg.)

045-U3

0-600 RPM speed range. 2.0" (51 mm) inlet/outlet; suitable to 450 PSI (31.0 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| R* | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CP | I | L | O | PORT SIZE | U +.000-.001 | 2X | U3 | U1/U2 | DIFF. BETWEEN U3 AND U1/U2 "R" DIM. |

|

| IN |

19.11

|

11.00 |

14.84

|

7.31

|

2.00

|

1.63

|

10.75 |

4.72

|

4.73 | SAME |

| MM |

485

|

279

|

377

|

186

|

---

|

41

|

273 |

120

|

120 | SAME |

*"R" dimension shown for customers converting from a U1/U2 pump to a U3 pump. All other dimensions are the same between U1/U2/U3.

NOTE: Dimension "2X" applies for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320-U3)

NOTE: Dimensions are for guidance purposes only. Contact your SPX FLOW Representative if more detailed measurements are needed.

Approximate shipping weight without motor or base 284 lb. (129 kg.)

060-U3

0-600 RPM speed range. 2.5" (64 mm) inlet/outlet; and 3.0" (76 mm) optional inlet/outlet; suitable to 300 PSI (20.7 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| R* | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CP | I | L | O | PORT SIZE | U +.000-.001 | 2X | U3 | U1/U2 | DIFF. BETWEEN U3 AND U1/U2 "R" DIM. |

|

| IN |

19.66

|

11.00 |

15.13

|

7.31

|

2.50

|

1.63

|

10.75 |

5.01

|

5.01 | SAME |

| MM |

499

|

279

|

384

|

186

|

---

|

41

|

273 |

127

|

127 | SAME |

*"R" dimension shown for customers converting from a U1/U2 pump to a U3 pump. All other dimensions are the same between U1/U2/U3.

NOTE: Dimension "2X" applies for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320-U3)

NOTE: Dimensions are for guidance purposes only. Contact your SPX FLOW Representative if more detailed measurements are needed.

Approximate shipping weight without motor or base 290 lb. (132 kg.)

064-U3 Rectangular Flange

0-400 RPM speed range. INLET: 2.44" x 9.0" OUTLET: 2½"; suitable to 300 PSI (20.7 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| AO | C | CA | CB | CC | CD | CP1 | FA | FB | HA | M | PA | PB | PC | PD | C | 2X | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 13.94 | 0.5 | 4 | 0.52 | 12.2 | NA | 21.91 | 5 | 13.23 | 0.53 | 0.48 | 2.53 | 9.09 | 1.24 | 2.07 | 4.94 | 10.31 |

| MM | 354 | 13 | 102 | 13 | 310 | NA | 557 | 127 | 336 | 13 | 12 | 64 | 231 | 31 | 53 | 125 | 262 |

Approximate shipping weight without motor or base 292 lb. (132 kg.)

130-U3

0-600 RPM speed range. 3.0" (76 mm) inlet/outlet; suitable to 200 PSI (13.8 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| R* | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CP | I | L | O | PORT SIZE | U +.000-.001 | 2X | U3 | U1/U2 | DIFF. BETWEEN U3 AND U1/U2 "R" DIM. |

|

| IN |

20.68

|

11.00 |

15.76

|

7.31

|

3.00

|

1.63

|

10.75 |

5.64

|

5.65 | SAME |

| MM |

525

|

279

|

400

|

186

|

---

|

41

|

273 |

143

|

144 | SAME |

*"R" dimension shown for customers converting from a U1/U2 pump to a U3 pump. All other dimensions are the same between U1/U2/U3.

NOTE: Dimension "2X" applies for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320-U3)

NOTE: Dimensions are for guidance purposes only. Contact your SPX FLOW Representative if more detailed measurements are needed.

Approximate shipping weight without motor or base 310 lb. (141 kg.)

134-U3 Rectangular Flange

0-400 RPM speed range. INLET: 3.19" x 9.38" OUTLET: 3"; suitable to 200 PSI (13.8 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| AO | C | CA | CB | CC | CD | CP1 | FA | FB | HA | M | PA | PB | PC | PD | C | 2X | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 13.94 | 0.78 | 3 | 0.63 | 14 | NA | 22.93 | 4.55 | 15.25 | 0.53 | 0.48 | 3.27 | 9.52 | 0.64 | 2.86 | 4.94 | 10.31 |

| MM | 354 | 20 | 76 | 16 | 356 | NA | 582 | 116 | 387 | 13 | 12 | 83 | 242 | 16 | 73 | 125 | 262 |

Approximate shipping weight without motor or base 312 lb. (142 kg.)

180-U3

0-600 RPM speed range. 3.0" (76 mm) inlet/outlet; suitable to 450 PSI (31.0 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| R* | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CP | I | L | O | PORT SIZE | U +.000-.001 | 2X | U3 | U1/U2 | DIFF. BETWEEN U3 AND U1/U2 "R" DIM. |

|

| IN |

23.48

|

14.80 |

19.03

|

9.38

|

3.00

|

2.00

|

13.06 |

4.21

|

4.20 | SAME |

| MM |

596

|

376

|

483

|

238

|

---

|

51

|

332 |

107

|

107 | SAME |

*"R" dimension shown for customers converting from a U1/U2 pump to a U3 pump. All other dimensions are the same between U1/U2/U3.

NOTE: Dimension "2X" applies for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320-U3)

NOTE: Dimensions are for guidance purposes only. Contact your SPX FLOW Representative if more detailed measurements are needed.

Approximate shipping weight without motor or base 498 lb. (226 kg.)

184-U3 Rectangular Flange

0-400 RPM speed range. INLET: 3.28" x 11.25" OUTLET: 3"; suitable to 450 PSI (31.0 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| AO | C | CA | CB | CC | CD | CP1 | FA | FB | HA | M | PA | PB | PC | PD | C | 2X | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 20.75 | 0.63 | 5.75 | 0.63 | 16.75 | 8.38 | 26.48 | 7 | 18 | 0.53 | 0.61 | 3.36 | 11.33 | 1.82 | 3.34 | 7.25 | 13.78 |

| MM | 527 | 16 | 146 | 16 | 425 | 213 | 673 | 178 | 457 | 13 | 15 | 85 | 288 | 46 | 85 | 184 | 350 |

Approximate shipping weight without motor or base 518 lb. (235 kg.)

210-U3

0-600 RPM speed range. 4.0" (102 mm) inlet/outlet; suitable to 500 PSI (34.5 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| R* | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CP | I | L | O | PORT SIZE | U +.000-.001 | 2X | U3 | U1/U2 | DIFF. BETWEEN U3 AND U1/U2 "R" DIM. |

|

| IN |

27.07

|

17.72 |

21.85

|

10.38

|

4.00

|

2.38

|

14.73 |

5.64

|

4.70 | 0.90 |

| MM |

688

|

450

|

555

|

264

|

---

|

60

|

374 |

143

|

119 | 24.3 |

*"R" dimension shown for customers converting from a U1/U2 pump to a U3 pump. All other dimensions are the same between U1/U2/U3.

NOTE: Dimension "2X" applies for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320-U3)

NOTE: Dimensions are for guidance purposes only. Contact your SPX FLOW Representative if more detailed measurements are needed.

Approximate shipping weight without motor or base 510 lb. (231 kg.)

214-U3 Rectangular Flange

0-400 RPM speed range. INLET: 3.45" x 12.70" OUTLET: 4"; suitable to 500 PSI (34.5 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| AO | C | CA | CB | CC | CD | CP1 | FA | FB | HA | M | PA | PB | PC | PD | C | 2X | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 35.94 | 0.75 | 7.5 | 0.75 | 16.5 | 8.25 | 29.06 | 9 | 18 | 0.69 | 1 | 3.55 | 12.8 | 2.73 | 2.6 | 8.81 | 17.46 |

| MM | 913 | 19 | 191 | 19 | 419 | 210 | 738 | 229 | 457 | 18 | 25 | 90 | 325 | 69 | 66 | 224 | 443 |

Approximate shipping weight without motor or base 754 lb. (342 kg.)

220-U3

0-600 RPM speed range. 4.0" (102 mm) inlet/outlet; suitable to 300 PSI (20.7 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| R* | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CP | I | L | O | PORT SIZE | U +.000-.001 | 2X | U3 | U1/U2 | DIFF. BETWEEN U3 AND U1/U2 "R" DIM. |

|

| IN |

24.22

|

14.80 |

18.49

|

9.38

|

4.00

|

2.00

|

13.25 |

4.45

|

4.44 | SAME |

| MM |

615

|

376

|

470

|

238

|

---

|

51

|

337 |

113

|

113 | SAME |

*"R" dimension shown for customers converting from a U1/U2 pump to a U3 pump. All other dimensions are the same between U1/U2/U3.

NOTE: Dimension "2X" applies for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320-U3)

NOTE: Dimensions are for guidance purposes only. Contact your SPX FLOW Representative if more detailed measurements are needed.

Approximate shipping weight without motor or base 748 lb. (339 kg.)

224-U3 Rectangular Flange

0-400 RPM speed range. INLET: 4.06" x 11.25" OUTLET: 4"; suitable to 300 PSI (20.7 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| AO | C | CA | CB | CC | CD | CP1 | FA | FB | HA | M | PA | PB | PC | PD | C | 2X | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 23.75 | 0.63 | 4.38 | 0.63 | 16.75 | NA | 27.22 | 5.63 | 18 | 0.53 | 0.5 | 4.17 | 11.36 | 0.73 | 3.32 | 6.25 | 12.88 |

| MM | 603 | 16 | 111 | 16 | 425 | NA | 691 | 143 | 457 | 13 | 13 | 106 | 289 | 18 | 84 | 159 | 327 |

Approximate shipping weight without motor or base 559 lb. (254 kg.)

320-U3

0-600 RPM speed range. 6.0" (152 mm) inlet/outlet; suitable to 300 PSI (20.7 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| R* | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CP | I | L | O | PORT SIZE | U +.000-.001 | 2X | U3 | U1/U2 | DIFF. BETWEEN U3 AND U1/U2 "R" DIM. |

|

| IN |

27.66

|

17.72 |

22.34

|

10.38

|

6.00 150# FLG

|

2.38

|

16.00 |

6.02

|

5.09 | 0.90 |

| MM |

703

|

450

|

567

|

264

|

---

|

60

|

406 |

153

|

129 | 23.9 |

*"R" dimension shown for customers converting from a U1/U2 pump to a U3 pump. All other dimensions are the same between U1/U2/U3.

NOTE: Dimension "2X" applies for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings (except 320-U3)

NOTE: Dimensions are for guidance purposes only. Contact your SPX FLOW Representative if more detailed measurements are needed.

Approximate shipping weight without motor or base 817 lb. (371 kg.)

324-U3 Rectangular Flange

0-400 RPM speed range. INLET: 4.25" x 12.70" OUTLET: 6"; suitable to 300 PSI (20.7 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| AO | C | CA | CB | CC | CD | CP1 | FA | FB | HA | M | PA | PB | PC | PD | C | 2X | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IN | 35.94 | 1.06 | 7.5 | 0.75 | 16.5 | 8.25 | 29.66 | 9.63 | 18 | 0.69 | 1 | 4.37 | 12.82 | 2.63 | 2.59 | 8.81 | 17.75 |

| MM | 913 | 27 | 191 | 19 | 419 | 210 | 753 | 244 | 457 | 18 | 25 | 111 | 326 | 67 | 66 | 224 | 451 |

Approximate shipping weight without motor or base 833 lb. (378 kg.)

Ports Standard: Sanitary Clamp Type connections available in a variety of styles including S-Line, I-Line and Q-Line

- Bevel Seat Available

- Optional European Types; DIN, SMS, RJT

- Male NPT and 150 lb. flanges optional on Models 006 through 220 size

- 150 lb. flanges standard on Model 320

- Optional aseptic ports

Rotors Standard: Twin Wing - Standard; suitable for most applications. Rotor clearance Standard: up to 300°F (149°C)

- Low viscosity clearance rotors optional for applications up to 200°F (93°C)

- Contact application engineering for other rotor clearance options

O-Rings Standard: Fluoroelastomer FKM Options:

- PTFE/FFKM

- Fluoroelastomer (FKM)

- Fluoroelastomer (FKM) - Class 6

- EPDM

- EPDM - SF

- EPDM - Class 6

- Silicone

- Perfluoroelastomer (FFKM)

- FEP Encapsulates

- Buna-N - Metal Detectable

- FKM - Metal Detectable

- EPDM - Metal Detectable

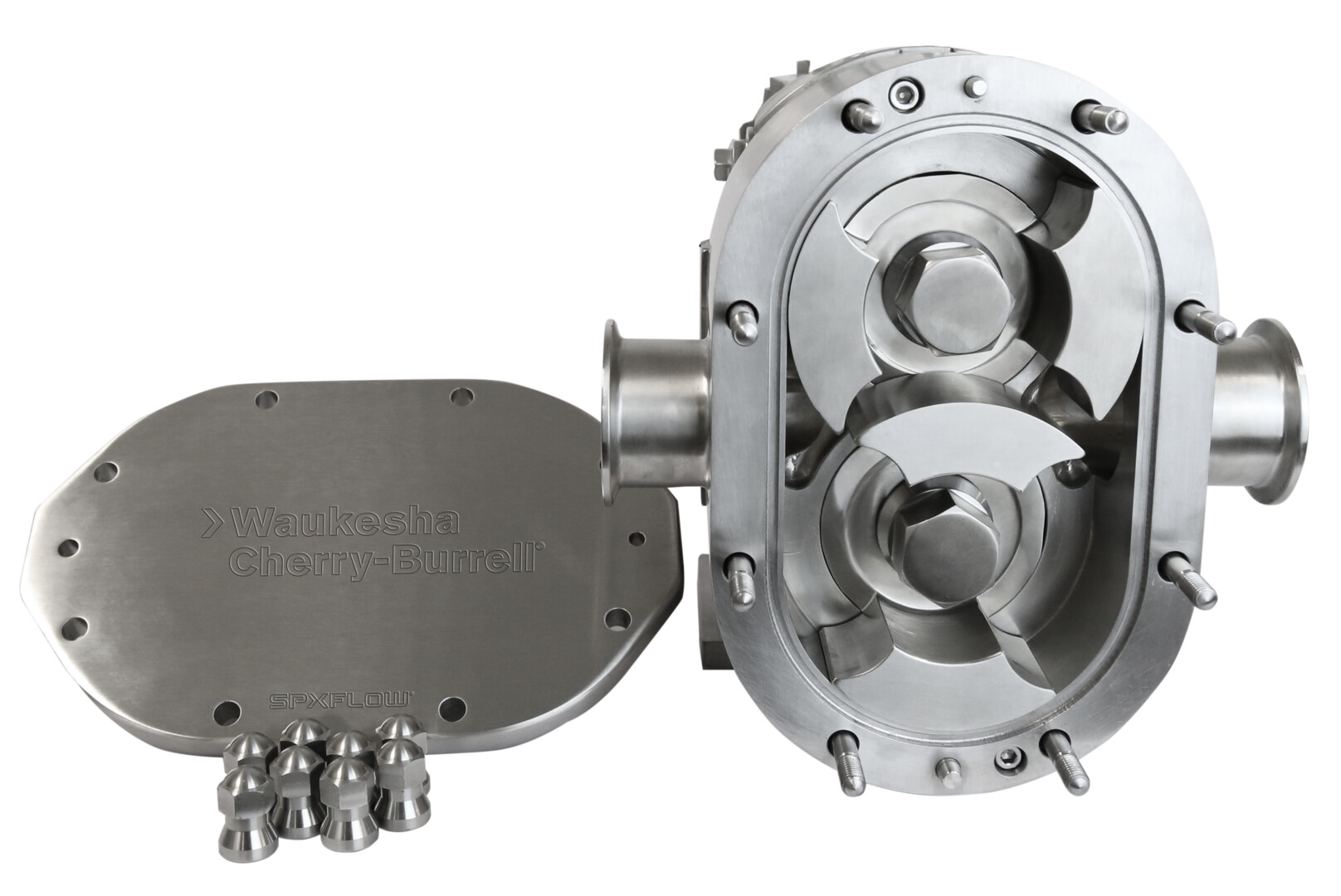

Seal Options Standard: Single Mechanical Seal Standard seal configuration: silicon carbide rotary seal face and carbon stationary seal face. Alternate materials available for abrasive service. Options:

- Double Concentric Mechanical Seal - Used with flushing fluid to cool, lubricate, flush away residue. Best arrangement for severe service.

- Single and Double O-ring Seal - Waukesha Cherry-Burrell's traditional general purpose seal. Low cost and easy to service. Suitable for low pressure applications. 100 psi, 7 bar

- Elastomer choices for o-rings: Fluoroelastomer (FKM), EPDM, Perfluoroelastomer (FFKM)

- Mechanical seal material options: carbon, silicon carbide, tungsten carbide

Cover & Gearcase Standard: Stainless steel 17-4 shafts, top shaft position, stainless steel bearing retainers, shaft completely sealed from product zone. Options:

- Lower shaft position

- Bearing isolators

- Pedestal shims for side mounted pumps. Left hand shaft position is standard

- Right hand shaft is positioned on side mounted gearcase

- Aseptic cover

- Jacketed cover

Shaft Position Standard: Top shaft position Options:

- Lower shaft position

Mounting Standard: Flat plate, epoxy painted, with adjustable feet, SS coupling guard, and Lovejoy or Woods coupling standard. Options:

- 304 SS unpolished plate base with adjustable feet

- Portable base with rubber wheels

- SS tubular bases

Bases & Drives Standard: Stainless steel tubular base with adjustable feet and stainless steel guard and coupling standard Options:

- 304 SS plate.

- Flat epoxy plate.

- Portable base.

Tru-Fit® Close coupled Tru-Fit® pump mounted on stainless steel base with stainless steel adaptors standard. Features:

- No shaft alignment necessary. No coupling guard required.

- Special base design enhances cleanability.

- Reduces overall length of complete unit by an average of 20-25%.

- Average of 20-25 gear ratios available per horsepower.

- Separate oil sump for gear reducer and timing gears.

Options:

- 304 SS polished plate base.

- NEMA or IEC frames available. Right angle reducer also available foradditional space savings.

- 1/2 through 60 horsepower drive options available.

- Horizontal or vertical porting.