Features & Benefits

Waukesha Cherry-Burrell® ECP Rotary Positive Displacement Pumps

For over 50 years, Waukesha Cherry-Burrell® has led the industry in designing, manufacturing, and applying external circumferential piston (ECP) style rotary positive displacement pumps. Trusted worldwide, Waukesha pumps deliver reliable performance with key sanitary and operational features.

Key Features

- 316L stainless steel body, cover, and shaft

- Easy disassembly for COP (Clean-Out-of-Place) cleaning

- FDA-compliant elastomers

- Aseptic models available

- Meets 3-A sanitary standards

️ Long-life Features

- Diffusion-hardened surfaces for rotor, body and cover available - ideal for abrasive or corrosive environments (3-A / FDA compliant)

- Pressure capability up to 200 psi (13.8 bar)

- No bearings in the product zone

- Heavy-duty bearing frame with large diameter shafts

- Grease-lubricated bearings for consistent performance across speed, temperature, and pressure ranges

- Non-galling Waukesha “88” alloy rotors:

- Allows tighter clearances

- Handles a wide range of viscosities

- Remanufacturing and Inspect & Advise programs to extend pump life and reduce costs

Installation Features

- Bidirectional flow with rotors secured by double jam nuts

- No restrictions on flow direction or shaft position

- Versatile 3-way gear case mounting, including vertical port alignment

- Upper or lower shaft positioning options

- Easy conversion from single O-ring to mechanical seals

- Interchangeable installation dimensions with other Universal Series pumps

Explore more about our eXpress app pump services.

Key Applications

Food & Beverage

- Soups, Stews, Tomato Pastes

- Vegetables, Dressings

- Chocolate, Fats & Oils

- Batters, Cream Fillings

- Brewery, Wort

- Soft / Fruit Drinks

- Meat Processing

Dairy

- Cream, Milk

- Cheese Curd & Whey

- Cottage Cheese

- Yogurt

Pharmaceutical / Cosmetics

- Pill Pastes

- Syrups, Extracts, Slurries

- Face Creams & Lotions

- Hair Styling Gels & Liquids

- Dyes & Alcohols

- Soaps

- Cosmetics

Chemicals / Industrial

- Solvents, Paints

- Fuels

- Resins, Polymers & Sludges

- Oil & Lubricants

| MODEL | DISPLACEMENT PER REVOLUTION |

NOMINAL CAPACITY TO |

MAXIMUM PRESSURE |

|---|---|---|---|

| 006-U1 | 0.0082 GAL. (0.031 Liter) | 6 GPM (1.3 m³/hr.) | 200 PSI (13.8 bar) |

| 015-U1 | 0.0142 GAL. (0.054 Liter) | 9 GPM (2.0 m³/hr.) | 200 PSI (13.8 bar) |

| 018-U1 | 0.029 GAL. (0.110 Liter) | 17 GPM (3.8 m³/hr.) | 200 PSI (13.8 bar) |

| 030-U1 | 0.060 GAL. (0.227 Liter) | 36 GPM (8.2 m³/hr.) | 200 PSI (13.8 bar) |

|

040-U1

|

0.076 GAL. (0.288 Liter)

|

45 GPM (10.2 m³/hr.)

|

150 PSI (10.3 bar)

|

| 060-U1 | 0.153 GAL. (0.579 Liter) | 90 GPM (20.4 m³/hr.) | 200 PSI (13.8 bar) |

| 130-U1 | 0.254 GAL. (0.961 Liter) | 150 GPM (34.1 m³/hr.) | 200 PSI (13.8 bar) |

| 220-U1 | 0.522 GAL. (1.976 Liter) | 310 GPM (70.4 m³/hr.) | 200 PSI (13.8 bar) |

| 320-U1 | 0.754 GAL (2.854 Liter) | 450 GPM (102 m³/hr.) | 200 PSI (13.8 bar) |

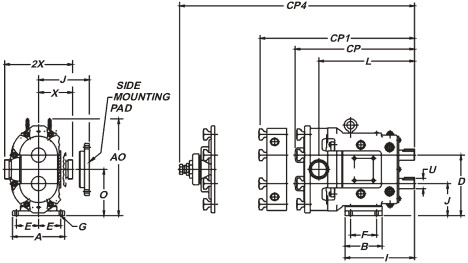

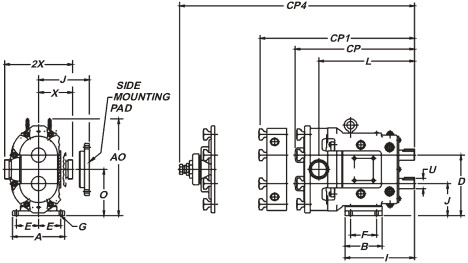

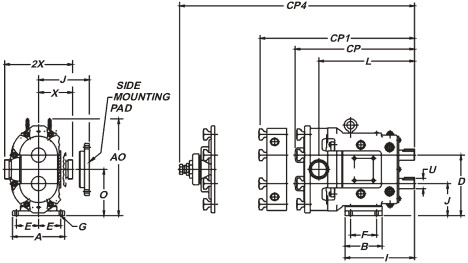

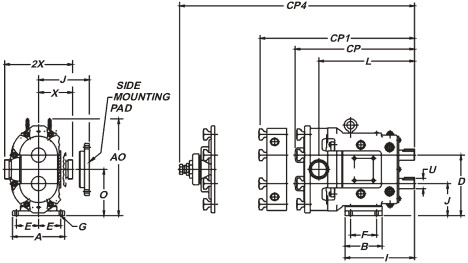

MODEL 006-U1

0-800 RPM speed range. 1" standard port size; optional 1½" and 2" port sizes available; suitable to 200 PSI (13.8 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| A | AO | B | CP | CP1 | CP4 | D | E | F | G | I | J | L | O | U | X | 2X | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN |

4.75 |

8.30 |

3.75 |

12.04 |

13.47 |

15.25 |

5.50 |

1.94 |

2.31 |

.41,SLOT |

7.66 |

2.93 |

9.61 |

4.21 |

0.875 |

3.49 |

6.97 |

|

MM |

121 |

211 |

95 |

306 |

342 |

387 |

140 |

49 |

59 |

10,SLOT |

194 |

74 |

244 |

107 |

22 |

89 |

177 |

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are ¾"-14 NPT on Models 006-U1 to 030-U1, 1"-11-½ NPT on Models 060-U1 and 130-U1.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings.

Approximate shipping weight 60 lb. (27 kg.)

NOTE: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed.

Additional Dimensions: Universal 1 Series Tru-Fit® Dimensions

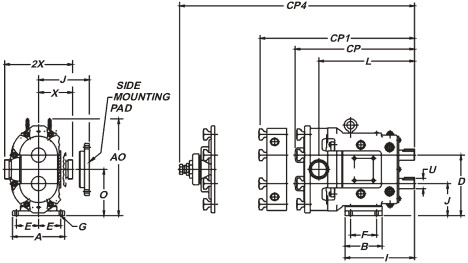

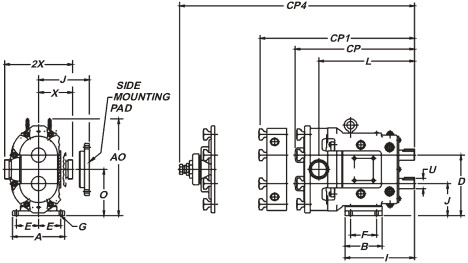

MODEL 015-U1

0-700 RPM speed range. 1½" standard port size; optional 1" and 2" port sizes available; suitable to 200 PSI (13.8 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| A | AO | B | CP | CP1 | CP4 | D | E | F | G | I | J | L | O | U | X | 2X | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

4.75

|

8.30

|

3.75

|

12.04

|

13.47

|

15.25

|

5.50

|

1.94

|

2.31

|

.41,SLOT

|

7.66

|

2.93

|

9.61

|

4.21

|

0.875

|

3.49

|

6.97

|

|

MM

|

121

|

211

|

95

|

306

|

342

|

387

|

140

|

49

|

59

|

10,SLOT

|

194

|

74

|

244

|

107

|

22

|

89

|

177

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are "-14 NPT on Models 006-U1 to 030-U1, 1"-11- NPT on Models 060-U1 and 130-U1.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings.

Approximate shipping weight 60 lb. (27 kg.)

NOTE: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed.

Additional Dimensions: Universal 1 Series Tru-Fit® Dimensions

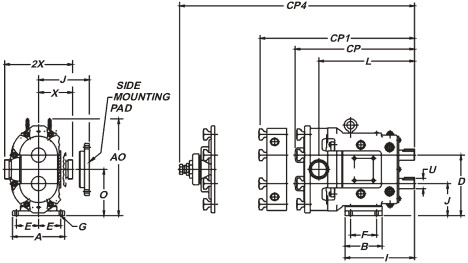

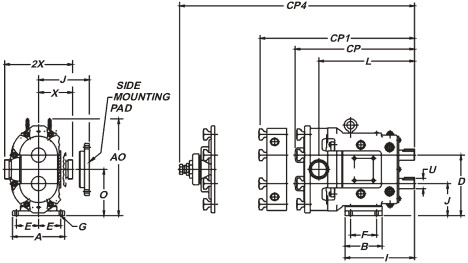

MODEL 018-U1

0-600 RPM speed range. 1½" standard port size; optional 1" and 2" port sizes available; suitable to 200 PSI (13.8 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| A | AO | B | CP | CP1 | CP4 | D | E | F | G | I | J | L | O | U | X | 2X | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

4.75

|

8.30

|

3.75

|

12.46

|

13.90

|

15.67

|

5.50

|

1.94

|

2.31

|

.41,SLOT

|

7.66

|

2.93

|

9.84

|

4.21

|

0.875

|

3.55

|

7.09

|

|

MM

|

121

|

211

|

95

|

316

|

353

|

398

|

140

|

49

|

59

|

10,SLOT

|

194

|

74

|

250

|

107

|

22

|

90

|

180

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are "-14 NPT on Models 006-U1 to 030-U1, 1"-11- NPT on Models 060-U1 and 130-U1.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings.

Approximate shipping weight 64 lb. (29 kg.)

NOTE: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed.

Additional Dimensions: Universal 1 Series Tru-Fit® Dimensions

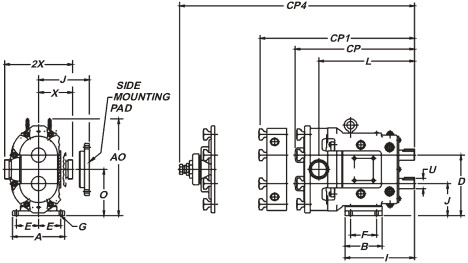

MODEL 030-U1

0-600 RPM speed range. 1½" standard port size; optional 1" and 2" port sizes available; suitable to 150 PSI (10 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| A | AO | B | CP | CP1 | CP4 | D | E | F | G | I | J | L | O | U | X | 2X | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

6.25

|

10.29

|

4.25

|

14.58

|

16.42

|

17.67

|

6.86

|

2.31

|

2.56

|

.41,SLOT

|

8.83

|

3.56

|

11.61

|

5.21

|

1.250

|

4.25

|

8.50

|

|

MM

|

159

|

261

|

108

|

370

|

417

|

449

|

174

|

59

|

65

|

10,SLOT

|

224

|

90

|

295

|

132

|

32

|

108

|

216

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are "-14 NPT on Models 006-U1 to 030-U1, 1"-11- NPT on Models 060-U1 and 130-U1.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings.

Approximate shipping weight 130 lb. (59 kg.)

NOTE: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed.

Additional Dimensions: Universal 1 Series Tru-Fit® Dimensions

MODEL 040-U1

0-600 RPM speed range. 2" standard port size; optional 1½" and 2½" port sizes available; suitable to 200 PSI (13.8 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| A | AO | B | CP | CP1 | CP4 | D | E | F | G | I | J | L | O | U | X | 2X | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

6.25

|

10.29

|

4.25

|

14.87

|

16.87

|

17.96

|

6.86

|

2.31

|

2.56

|

.41slot

|

8.83

|

3.56

|

11.99

|

5.21

|

1.25

|

4.31

|

8.62

|

|

MM

|

159

|

261

|

108

|

378

|

428

|

456

|

174

|

59

|

65

|

10 slot

|

224

|

90

|

305

|

132

|

31.75

|

109

|

219

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are "-14 NPT on Models 006-U1 to 030-U1, 1"-11- NPT on Models 060-U1 and 130-U1.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings.

Approximate shipping weight 140 lb. (64 kg.)

NOTE: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed.

Additional Dimensions: Universal 1 Series Tru-Fit® Dimensions

MODEL 060-U1

0-600 RPM speed range. 2½" standard port size; optional 2" and 3" port sizes available; suitable to 200 PSI (13.8 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| A | AO | B | CP | CP1 | CP4 | D | E | F | G | I | J | L | O | U | X | 2X | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

8.25

|

15.31

|

5.87

|

18.91

|

20.69

|

22.07

|

9.56

|

3.50

|

4.12

|

.53

|

10.99

|

5.06

|

15.14

|

7.31

|

1.625

|

5.37

|

10.75

|

|

MM

|

210

|

389

|

149

|

480

|

526

|

561

|

243

|

89

|

105

|

13

|

279

|

129

|

385

|

186

|

41.28

|

136

|

273

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are "-14 NPT on Models 006-U1 to 030-U1, 1"-11- NPT on Models 060-U1 and 130-U1.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings.

Approximate shipping weight 285 lb. (130 kg.)

NOTE: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed.

Additional Dimensions: Universal 1 Series Tru-Fit® Dimensions

MODEL 130-U1

0-600 RPM speed range. 3" standard port size; optional 2½" and 4" port sizes available; suitable to 200 PSI (13.8 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| A | AO | B | CP | CP1 | CP4 | D | E | F | G | I | J | L | O | U | X | 2X | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

8.25

|

15.31

|

5.87

|

19.85

|

21.63

|

23.01

|

9.56

|

3.50

|

4.12

|

.53

|

10.99

|

5.06

|

15.77

|

7.31

|

1.625

|

5.37

|

10.75

|

|

MM

|

210

|

389

|

149

|

504

|

549

|

584

|

243

|

89

|

105

|

13

|

279

|

129

|

401

|

186

|

41.28

|

136

|

273

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are "-14 NPT on Models 006-U1 to 030-U1, 1"-11- NPT on Models 060-U1 and 130-U1.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings.

Approximate shipping weight 305 lb. (138 kg.)

NOTE: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed.

Additional Dimensions: Universal 1 Series Tru-Fit® Dimensions

MODEL 220-U1

0-600 RPM speed range. 4" standard port size; optional 3" and 6" port sizes available; suitable to 200 PSI (13.8 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| A | AO | B | CP | CP1 | CP4 | D | E | F | G | I | J | L | O | U | X | 2X | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

8.50

|

19.13

|

9.00

|

23.37

|

--

|

27.87

|

12.38

|

3.75

|

7.25

|

.53,SLOT

|

14.80

|

6.38

|

18.49

|

9.38

|

2.00

|

6.63

|

13.25

|

|

MM

|

216

|

486

|

229

|

594

|

--

|

708

|

314

|

95

|

184

|

13,SLOT

|

376

|

162

|

470

|

238

|

50.80

|

168

|

337

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are "-14 NPT on Models 006-U1 to 030-U1, 1"-11- NPT on Models 060-U1 and 130-U1.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings.

Approximate shipping weight 565 lb. (256 kg.)

NOTE: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed.

Additional Dimensions: Universal 1 Series Tru-Fit® Dimensions

MODEL 320-U1

0-600 RPM speed range. 6", 150# flanged standard port size; suitable to 200 PSI (13.8 bar) differential pressure. Temperature range -40°F (-40°C) to 300°F (149°C).

| A | AO | B | CP | CP1 | CP4 | D | E | F | G | I | J | L | O | U | X | 2X | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

IN

|

12.00

|

22.38

|

11.63

|

30.17

|

--

|

--

|

13.88

|

5.25

|

8.00

|

.66

|

17.80

|

6.88

|

21.92

|

10.38

|

2.375

|

8.00

|

16.00

|

|

MM

|

305

|

568

|

295

|

766

|

--

|

--

|

353

|

133

|

203

|

17

|

452

|

175

|

557

|

264

|

60.45

|

203

|

406

|

CP= Standard Cover, CP1= Jacketed Cover, CP4= Manual Vented Cover, Connection sizes for Jacketed Covers are "-14 NPT on Models 006-U1 to 030-U1, 1"-11- NPT on Models 060-U1 and 130-U1.

Dimension 'X' and '2X' apply for Bevel Seat, "S"-Clamp, "Q"-Clamp, 15I and 14I fittings.

Approximate shipping weight 900 lb. (408 kg.)

NOTE: Dimensions are for guidance purposes only. Contact your WCB Representative if more detailed measurements are needed.

Additional Dimensions: Universal 1 Series Tru-Fit® Dimensions

Body Standard: 316L Stainless Steel, Body retaining screws Options:

- Flush taps for future double seals

Ports Standard: S-Line Options:

- Bevel Seat, I-Line, Q-Line; European DIN, SMS or RJT

- Male NPT, 150 lb. & 300 lb. Flanges. (150 lb. standard on Model 320)

- Rectangular Flange Inlet or Aseptic ports

- Extended ports

- Optional port sizes on 6, 18, 30 and 60 Models

Covers Standard: 316L SS plain cover with 3-Wing cover nuts Options:

- Vent or drain connections

- Aseptic, jacketed or vented

- Hex cover nuts

Rotors Standard: Alloy 88 Twin Wing. Standard clearance for up to 180° F (82° C) Options:

- Hot clearance to 300° F (149° C)

- Clearance above 300° F (149° C) on application

- Special & front face clearances and slotted rotor hub for special applications

- Single wing for 30, 60, 130 and 220 models for minimal particulate damage

O-Rings Standard: Buna-N Options:

- Fluoroelastomer (FKM)

- EPDM

- Silicone

- Perfluoroelastomer (FFKM)

- FEP Encapsulates

Seals Standard: Single Buna-N O-Rings with Zirconia sleeve Options:

- 316L SS sleeve

- Double O-Ring Seal with Flush Connection

- Single Mechanical Seal with Carbon (One Piece) vs. Ceramic Seal Faces

- Double Mechanical Seal with outer Carbon Seal Face & Flush Connections

- Triple lip seals available for reliable performance in chemically aggressive applications or certain COP sanitary applications. Available upon request.

- Ceramic, Chrome Oxide, Silicon Carbide Seal Faces

- Two piece carbon inner seal

Gearcase Standard: Cast iron powder coated, 316L SS shafts, top shaft position, stainless steel bearing retainers, left hand shaft position Options:

- Stainless Steel gearcase

- Steel-It paint

- 17-4 PH shafts

- Lower shaft position

- Bearing Isolators

- Pedestal shims for side mounted pumps.

- Right hand shaft position on side mounted gearcase

Bases Standard: Flat plate, epoxy painted, with adjustable feet, SS coupling guard, and Lovejoy or Woods coupling Options:

- 304 SS unpolished plate base with adjustable feet

- Portable base with rubber wheels

- SS tubular bases

Drives

- WCB ISR Integral Speed Reducer Sizes 49, 79 and 239

- Direct connected gear motors

Tru-Fit® Close coupled Tru-Fit® pump mounted on stainless steel base with stainless steel adaptors standard. Features:

- No shaft alignment necessary. No coupling guard required.

- Special base design enhances cleanability.

- Reduces overall length of complete unit by an average of 20-25%.

- Average of 20-25 gear ratios available per horsepower.

- Separate oil sump for gear reducer and timing gears.

Options:

- 304 SS polished plate base.

- NEMA or IEC frames available. Right angle reducer also available for additional space savings.

- 1/2 through 60 horsepower drive options available.

- Horizontal or vertical porting.

Click on the links below to download pump model performance curves for Universal 1 Series Positive Displacement pumps.

Download Instructions for Reading Positive Displacement Pump Curves || PDF

- Universal 1 Series - Model 006 - Performance Curve - 95-07133 || PDF

- Universal 1 Series - Model 015 - Performance Curve - 95-07134 || PDF

- Universal 1 Series - Model 018 - Performance Curve - 95-07135 || PDF

- Universal 1 Series - Model 030 - Performance Curve - 95-07136 || PDF

- Universal 1 Series - Model 040 - Performance Curve - 95-07241 || PDF

- Universal 1 Series - Model 060 - Performance Curve - 95-07137 || PDF

- Universal 1 Series - Model 130 - Performance Curve - 95-07138 || PDF

- Universal 1 Series - Model 220 - Performance Curve - 95-07139 || PDF

- Universal 1 Series - Model 320 - Performance Curve - 95-07140 || PDF