STORIES IN THE MAKING

Enabling Carbon Capture: The Critical Role of Pumps in the Energy Transition

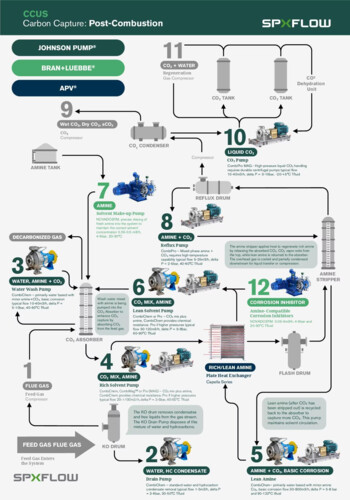

As global industries accelerate their journey toward net-zero emissions, Carbon Capture, Utilization, and Storage (CCUS) is emerging as a foundational technology. It offers a viable path to decarbonize hard-to-abate sectors like cement, steel, refining, and chemicals, industries that are vital to modern life but historically difficult to decarbonize. At SPX FLOW, we are proud to support this transformation with advanced pumping solutions engineered for the unique challenges of CCUS systems.

What Is CCUS?

CCUS refers to the process of capturing carbon dioxide (CO₂) emissions at their source, such as industrial plants or power facilities, and either reusing the CO₂ in industrial processes or storing it underground in geological formations, or it’s being pumped deep down into the ocean.

When implemented effectively, CCUS can reduce carbon emissions by up to 90%, making it an essential tool in global decarbonization strategies.

But CCUS is not a one-size-fits-all solution. It includes multiple stages: capture, compression, transport, utilization, and storage. Each has its own technical demands, and pumps play a critical role at every stage, ensuring the safe, efficient, and continuous movement of complex fluids under extreme pressures and temperatures.

The Unsung Hero: Pumping Solutions for CCUS

Pumps are often overlooked in conversations about CCUS technology, yet they are central to system performance and reliability. SPX FLOW offers a diverse range of pumping technologies tailored for the rigorous demands of CCUS applications, with a focus on chemical compatibility, high-pressure performance, and long-term durability.

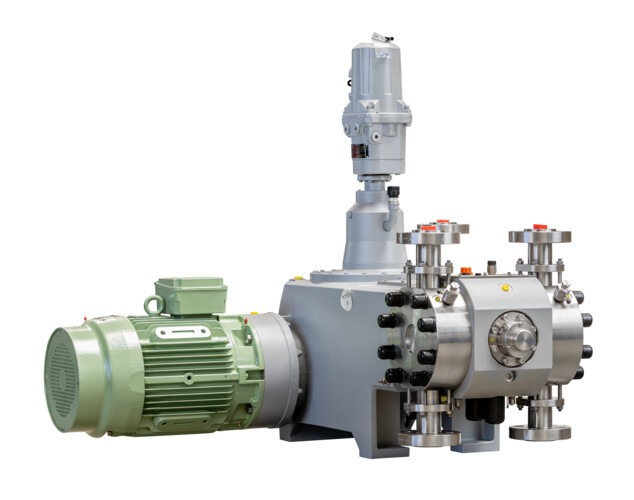

Solvent Injection – NOVADOS® Metering Pumps

"CO₂ is commonly captured using amine-based solvents in absorption towers. NOVADOS metering pumps deliver precise and continuous dosing of these solvents, ensuring optimal CO₂ absorption efficiency.

- High-pressure performance: Up to 500 bar+

- Dosing precision: Enables consistent absorption efficiency

- Material compatibility: Suitable for aggressive amines and solvents

Chemical Dosing – NOVADOS® Metering Pumps

In the post-capture phase, chemical additives are often injected to manage corrosion or support downstream processes. NOVADOS metering pumps provide robust, accurate, and leak-free dosing performance in these critical operations.

- Precise chemical dosing with excellent material compatibility

- Leak-free diaphragm design for safe and reliable operation

- Modular configurations for flexible, high-pressure applications

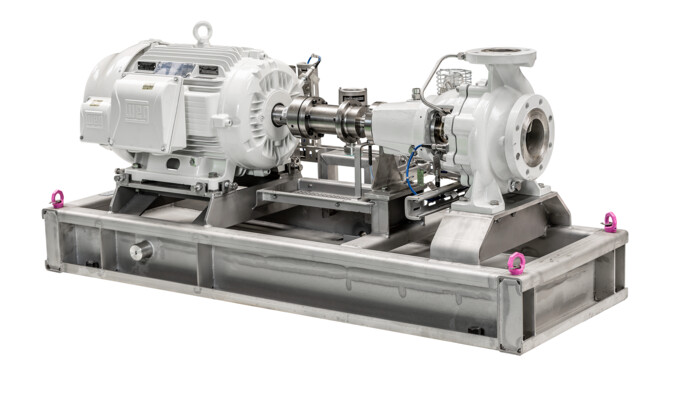

Transfer of Rich and Lean CO₂, Water, and Amines – CombiPro™, CombiChem™ & CombiTherm™ Pumps

Once captured, CO₂ and related process fluids must be circulated, cooled, or transported in liquefied or mixed forms. CombiPro, CombiChem, and CombiTherm pumps are engineered for thermal and mechanical stability in these demanding environments.

- Pressure tolerance: Up to 35 bar

- Thermal resilience: Up to 350°C

- Application-ready: Ideal for rich and lean amine circulation, liquefaction loops, and pipeline injection systems