STORIES IN THE MAKING

Is a Scraped Surface Heat Exchanger Your Missing Ingredient?

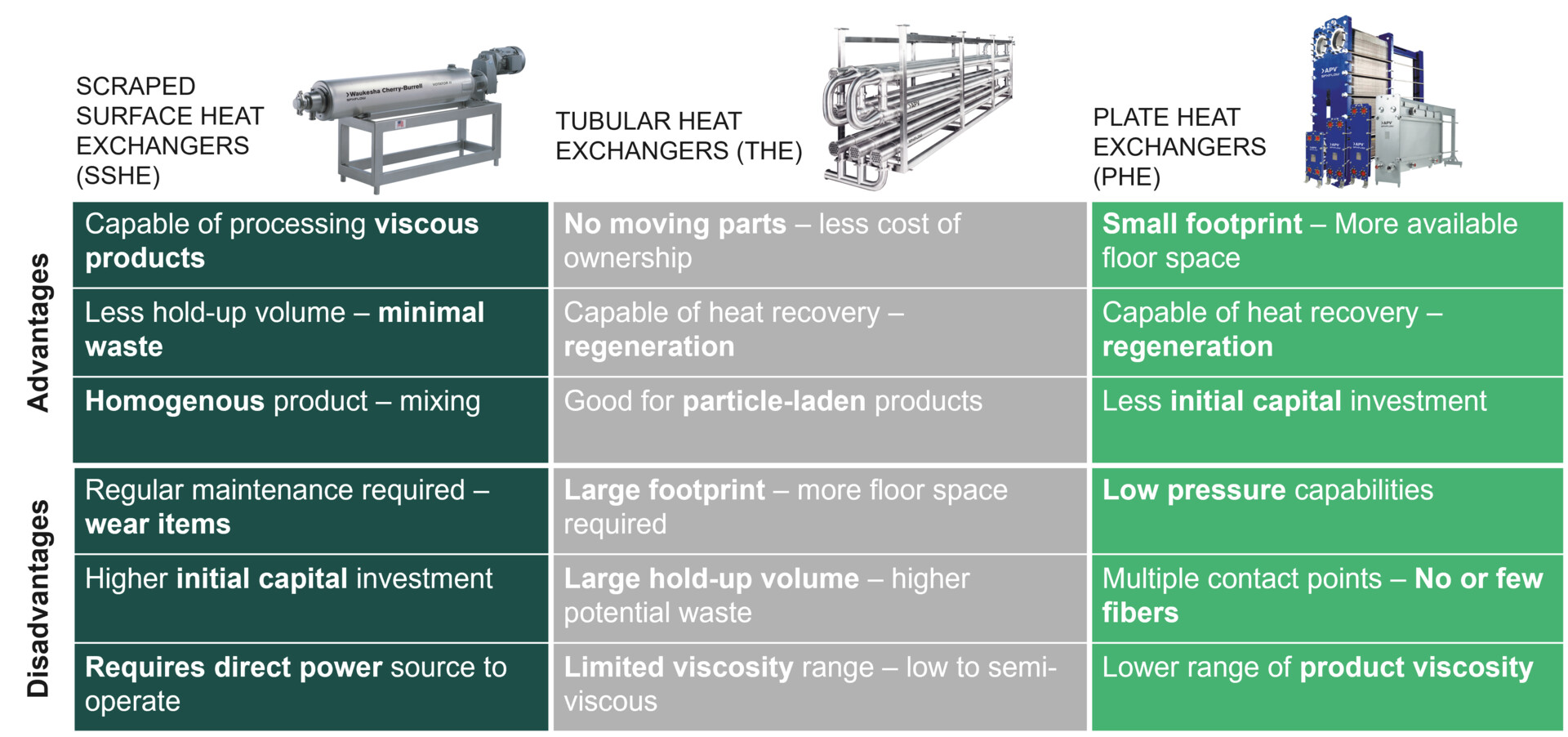

Whether you're processing cream cheese, peanut butter, syrups or greases, choosing the right heat exchanger is critical to the quality of the end product. And while plate and tubular systems are commonly used in food, beverage and industrial applications, they often fall short when viscosity spikes or phase-changes are involved. That’s where scraped surface heat exchangers (SSHEs) stand out. But how do you know when a SSHE is the right fit?

How Scraped Surface Heat Exchangers Work—and Why They Matter

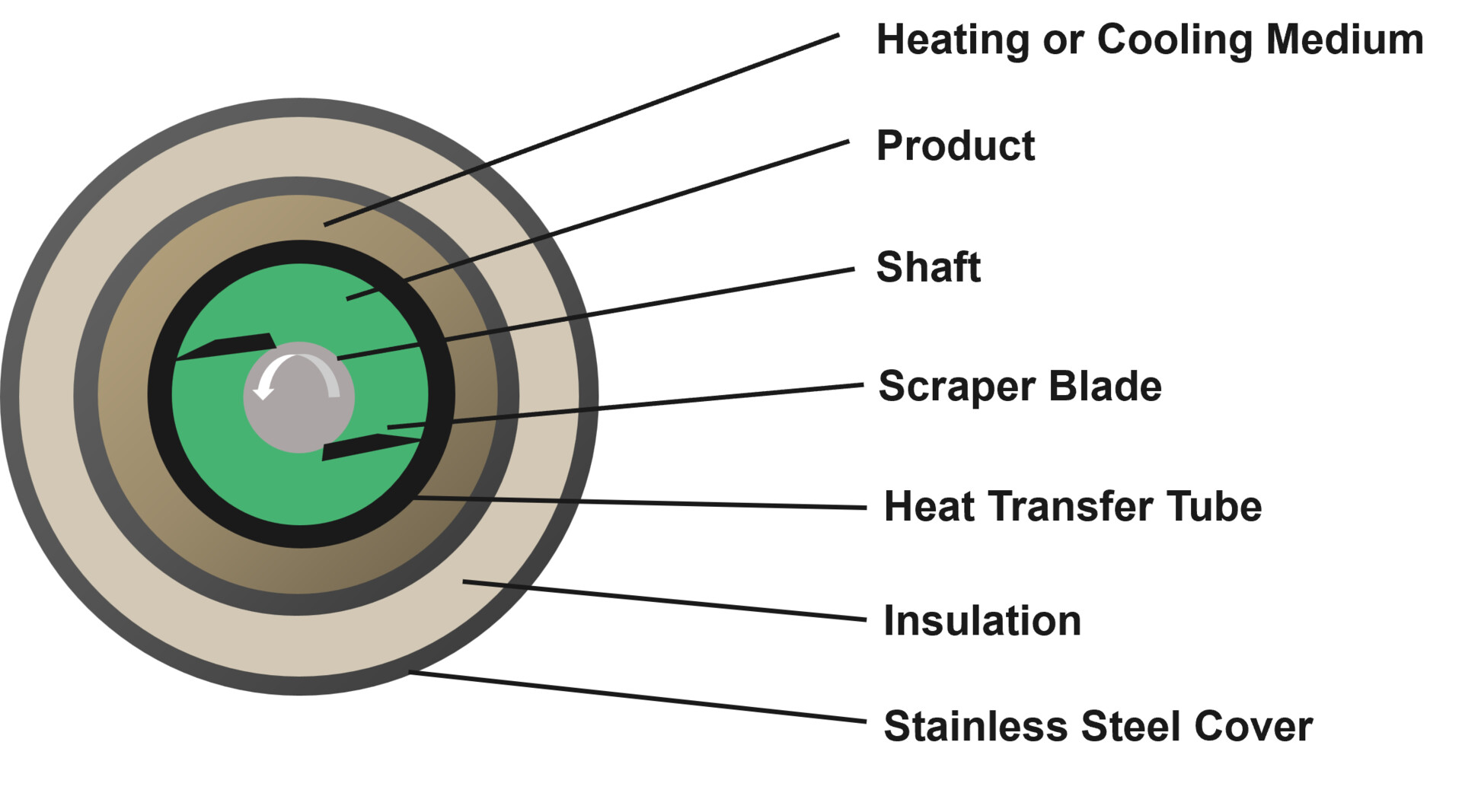

A scraped surface heat exchanger uses a rotating shaft with blades to continuously remove product buildup from the heat transfer wall. This prevents fouling, reduces burn-on or freezing and enables efficient heat transfer. SSHEs handle a broad viscosity range—from yogurt to greases—and manage complex processes like crystallization, slush freezing and gelatinization.

Three Key Reasons to Choose SSHEs

1. Handles Thick or Shear-Sensitive Products

When flow is a challenge—like with cold cream cheese, peanut butter or meat slurries—SSHEs maintain consistent thermal performance. Unlike plate or tubular exchangers, they continuously renew the boundary layer through scraping. The Votator® II is engineered for ultra-high viscosities and designed for concentric, eccentric and oval tube options to match flow dynamics and torque needs.

2. Manages Phase Changes with Control

Crystallization, slush freezing and gelatinization can cause sudden viscosity shifts. SSHEs handle these transitions while preserving product integrity, whether oils are plasticizing or starches are thickening. Additionally, scraping prevents ice or solid buildup—which is especially important when using ammonia or CO₂ as refrigerants.

3. Reduces Waste, Increases Yield

With high-value or sensitive products, every drop matters. SSHEs minimize hold-up volume while enabling continuous, homogeneous mixing—improving batch consistency and reducing product loss.

Not Just for Food – Think Beyond the Plate to Industrial & Personal Care

While SSHEs are a staple in dairy, bakery and prepared foods, they also excel in industrial and personal care applications. From petroleum jelly and wax emulsions to mascara, printing ink and roofing sealants—any product that’s viscous or thermally complex can benefit from this technology.

We’ve seen SSHEs improve line stability and product quality in industries transitioning from inefficient batch processes to more controlled continuous operations.

When to Consider SSHE Over Plate or Tubular Systems

Here’s a quick breakdown of where SSHEs outperform:

Selecting the Right Scraped Surface Unit

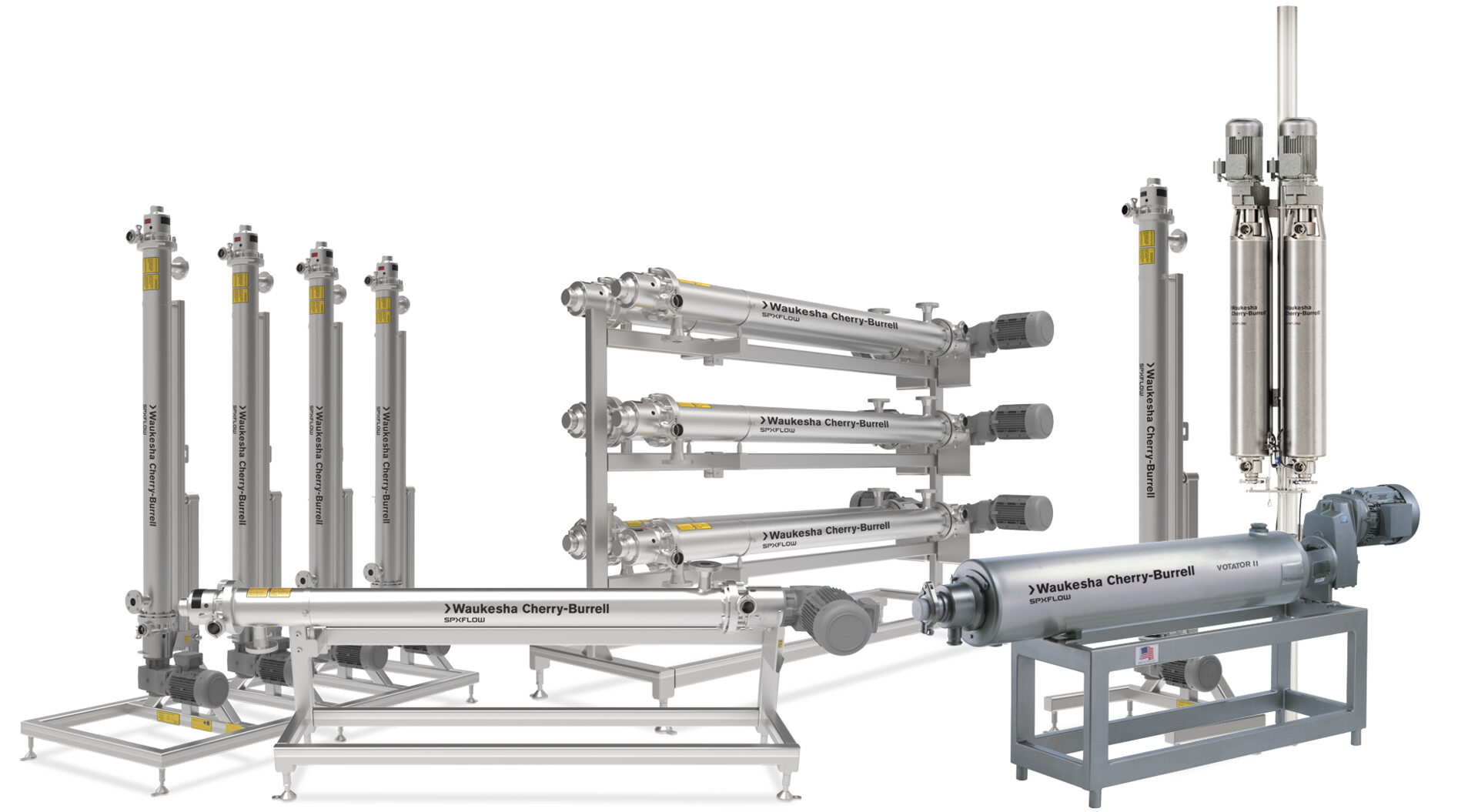

SPX FLOW’s Waukesha Cherry-Burrell Votator® Series has delivered consistent results for more than 80 years, and offers two primary SSHE platforms:

Votator® Origin Series: Designed for low-to-medium viscosity products (up to 15,000 cP), the Origin is ideal for applications that don’t require refrigerants and benefit from the mechanically assisted scraping action of the blades.

Votator® II Series includes the Votator® II Horizontal, Votator® Extra Heavy Duty and Votator® II Vertical. Built for heavy-duty high-viscosity applications, the Votator II series offers multiple tube configurations, refrigeration compatibility and upgraded vertical lift systems to simplify teardown and inspection. And for plants with space constraints our vertical designs and retrofit kits make integration and servicing more accessible than ever.

Is a SSHE the Right Fit?

Ask yourself:

- Are you experiencing inconsistent product quality, coloring or consistency with your current heating or cooling process?

- Would your product benefit from a homogeneous temperature profile?

- Is the product sticky or likely to foul the heat transfer surface?

- Are you ready to upgrade from a batch to a continuous process?

If the answer to any of these is yes, a Votator SSHE might be your missing ingredient.

Ready to find the right fit or need help determining whether a SSHE is right for you? Contact SPX FLOW or your authorized channel partner to connect with an application engineer.