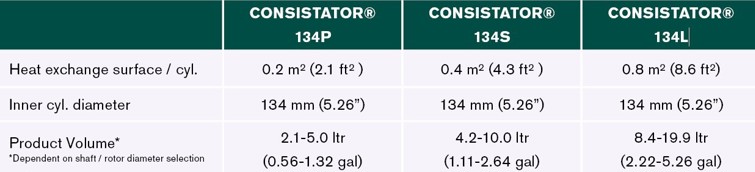

Gerstenberg Schrӧder Consistator Origin Series - Scraped Surface Heat Exchangers

Consistator Origin Series is designed for robust and efficient heat transfer. Offering application adaptability, flexible configuration and ease of maintenance.

FEATURES

The Gerstenberg Schroder Consistator Origin scraped surface heat exchanger is a versatile and robust system, specifically engineered to operate effectively even in harsh conditions. It is designed to heat or cool low and medium viscous products, with or without particles. This heat exchanger is compliant with 3-A sanitary requirements and is available in both horizontal and vertical configurations.

The horizontal design features a sturdy stainless-steel frame and can be expanded to accommodate up to six cylinders. The vertical design offers a manual "pivot-point" feature, allowing easy repositioning of the cylinder in production or service modes, while requiring minimal space.

With its adaptable platform and exceptional performance, the Gerstenberg Schroder Consistator Origin is the ideal choice for ensuring efficient heat exchange in demanding applications.

Application

- Heating

- Cooling

- Crystallization

- Pasteurization

- Sterilization

Benefits:

- Versatile and flexible configuration

- Offered in horizontal and vertical set-up

- Flexibility for different applications

- Easy and fast maintenance

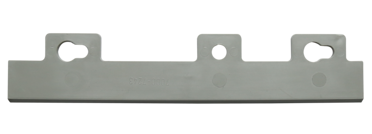

- Enhanced design of hinged scraper blade

- Choice of single and double mechanical cartridge seals

- Tangential ports for improved functionality

- Supported by a team of skilled and experienced engineers