Products

- Analyzers

- Automation Systems

- Butter Equipment

- Centrifuges

- Cleaning-in-Place Systems

- Deareators

- Draught Regulators

- Evaporators

- Fat Crystalization Equipment

- Filters & Strainers

- Fluid Bed Dryers

- Heat Exchangers

- Homogenizers

- Membrane Filtration Systems

- Microparticulation Systems

- Mixers & Agitators

- Pasturization Systems

- Pigging Systems

- Plumbing Products

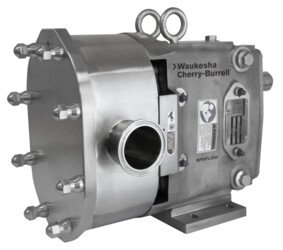

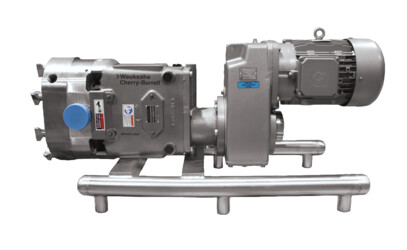

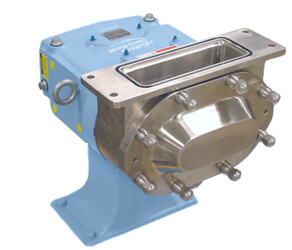

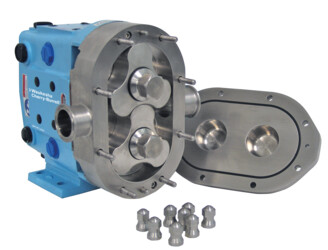

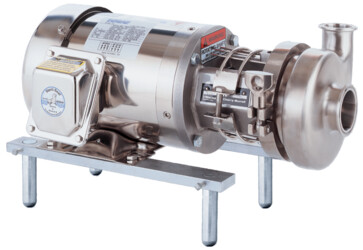

- Pumps

- Recreational Marine Products

- Recreational Marine Pumps

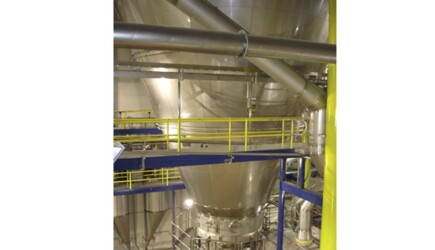

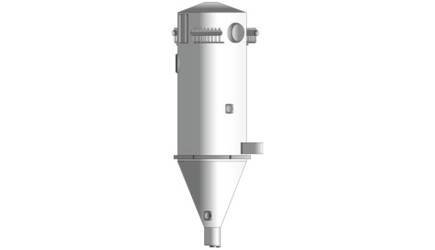

- Spin Flash Dryers

- Spray Dryers

- UHT Systems

- Valves

- Adhesives & Sealants

- Automotive Heating System

- Baby Food

- Bakery Filing Cream

- Beer, Cider, Wine & Spirits

- Biodiesel

- Boats & Watercraft

- Building Infrastructure

- Butter & Spreads

- Cement

- Cheese

- Chocolate

- Coffee & Tea

- Condiments, Sauces & Soups

- Cosmetics

- Dairy Powders

- Ethanol

- Flavors & Fragrances

- Fruit Juice

- Fuel Supply System

- Hair, Nail & Skin Care Products

- Ice Cream

- Inorganic Chemicals

- Margarine & Shortening

- Meat & Animal-Based Proteins

- Milk & Cream

- Neutralization

- Nutraceuticals

- Oral Care

- Paints & Coatings

- Petrochemicals

- Pipelines

- Plant-Based Food & Beverages

- Plastic & Resins

- Refinery

- Soft Drinks

- Solvents & Solutions

- Specialty Chemicals

- Synthetic Rubber

- Yogurt

Dairy

Innovative Dairy Processing Solutions for a Changing World

Dairy Processing in a Changing Market

Balancing Tradition with Innovation

While demand for traditional dairy products continues to grow, part of this growth is from consumers who would also like new dairy taste experiences, nutritional advantages, or more sustainably processed products. Meeting this demand puts pressure on dairy producers to improve operations for current offerings while innovating to gain market advantage.

Challenges of Dairy Production and Shelf Life

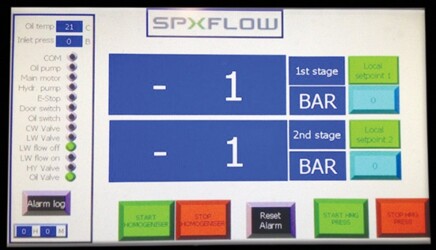

The Importance of Strict Process Control

Contributing to the challenge is the fact that dairy products are highly perishable. Backing up the “sell by” date on any package is a production system that enforces stringent control of flow, temperature, sanitation and numerous other variables. Even small variations at any point in the value chain could compromise quality significantly.

Processing a Wide Range of Dairy Products

Expertise Across Product Categories

Whether you are processing fresh, ESL, or functional milk; yogurt, spreadable cheese, or dessert; dried, agglomerated, evaporated or condensed milk products; or butter and spreads, our experienced experts can work with you to create the most appealing dairy products.

Optimizing Taste, Texture, and Shelf Stability

They know how to balance taste, optimize protein content and shelf life, ensure product stability, ensure spreadability or do whatever else it takes to bring great-tasting dairy products to grocery shelves. We have exemplary experience at every link of the dairy value chain. If it involves milk processing: we've been there, done that!

Why Dairy Producers Choose SPX FLOW

End-to-End Support from Design to Installation

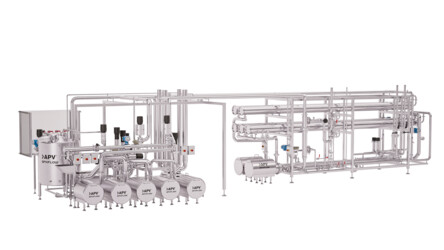

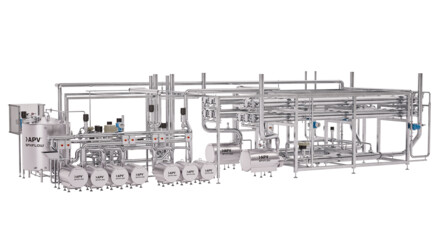

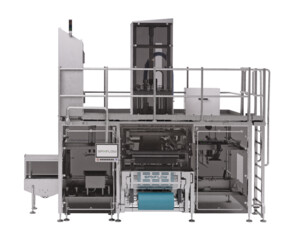

Dairy producers the world over rely on SPX FLOW for product development, design, engineering, and installation of everything from turnkey dairy process units to full-scale plants.

Improving Efficiency, Agility, and Sustainability

The processes we create with you will help you maximize product quality, production yield and food safety while minimizing raw material waste, operating costs, energy consumption, footprint and transportation costs for end products.

Your new processes will make you more agile to develop and produce products that meet changing market needs. Our extensive experience with project management of major capital projects makes us the ideal partner for your most challenging processing needs.

Advanced Dairy Processing Equipment

Proven Technologies for Every Dairy Application

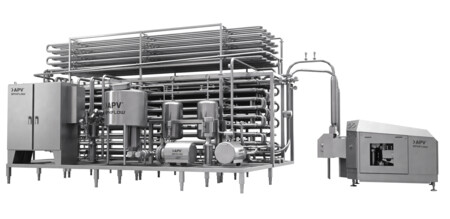

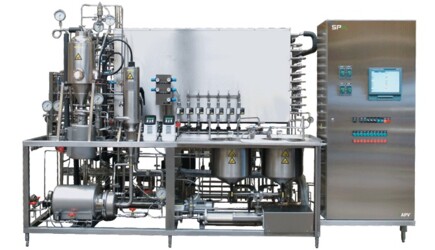

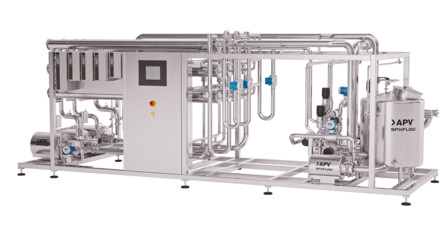

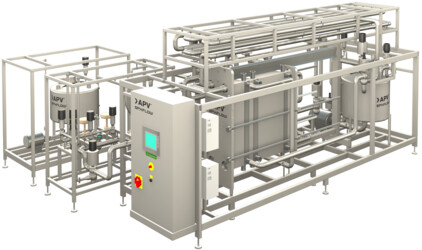

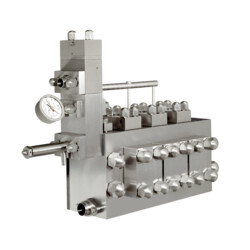

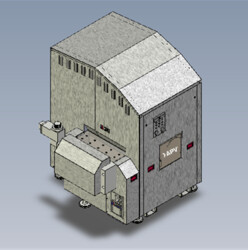

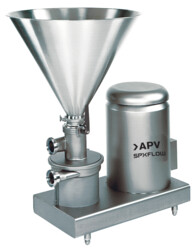

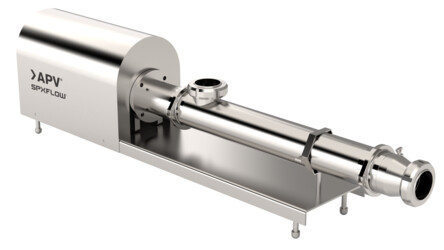

SPX FLOW has over a century of experience in dairy processing and invented several key innovative dairy processing components, including the APV Rannie and Gaulin Homogenizers (an industry standard milk homogenizer), the APV Compomaster for fat standardization, the APV Palarisator for UHT infusion, the APV Uperizer for UHT injection and the Gerstenberg Schröder Dairy Blend system for spreadable butter products.

Industry-Invented Solutions from SPX FLOW

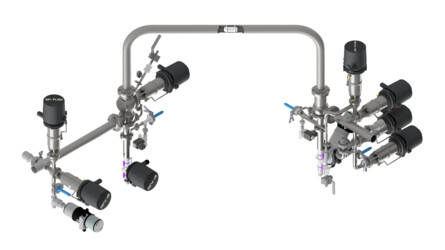

We offer systems for all your dairy production needs. This includes proven in the field systems for heat exchange, mixing and blending, membrane filtration, microparticulation, separation, homogenization, ultra-high temperature (UHT) treatment, butter technology, fermentation, evaporation, and drying.

Innovation and Product Development Support

From Market Opportunity to Final Product

Your success in bringing competitive dairy products to market begins with the recognition of a market opportunity and a recipe. SPX FLOW has the expertise to analyze market opportunities and work with you to develop a recipe and process that leverages your core competencies.

Global Innovation and Design Centers

We are constantly innovating on your behalf. Much of the development and testing takes place at our global Innovation and Design Centers, which provide a small-case multipurpose production facility and fully equipped laboratory to support product development and testing. We work with you to fine-tune your end product, including modifying the recipe, process, or equipment as needed to maximize market success.

See SPX FLOW global Innovation and Design Centers for more information.