Valves

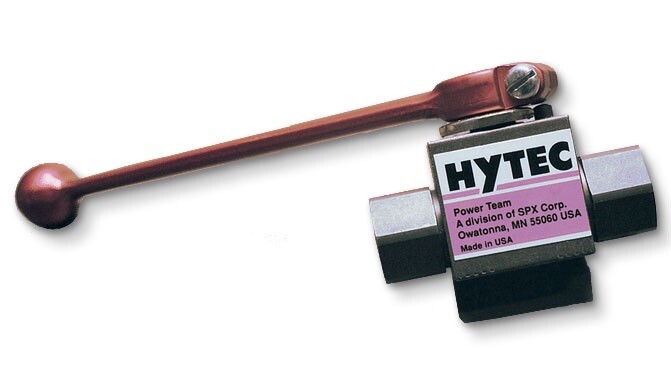

High Pressure Ball Valves

Designed for shifting under high differential pressures

Features

These two new high pressure ball valves provide full unrestricted flow and positive shut-off of fluids under extremely rugged service conditions making them perfect for workholding applications. Based on the “floating” ball principle, this design allows the ball to turn freely between the ball seals. A positive seal is attained by fluid pressure acting on the upstream surface of the ball and producing a constant uniform contact between the downstream ball seal and ball. The ball is operated by a single spindle with a projecting square end to which the handle is attached.

- Positive stops

- 90 degree actuation

- Easy Rotating

- Designed for shifting under high differential pressures

- Handle easily modified to fit application

- 5000 psi max.

- SAE or NPT ports

View Catalog - High Pressure Ball Valves - US

Both the 1⁄4 NPT “T” Port Check Valve (part number 500171) and the SAE-4 (part number 500173) are recommended on single acting circuits where there is more than one directional valve per power source. These check valves are ideal for use in circuits where return line pressure fluctuations may affect released clamps. Use this anytime a return line pressure spike could cause unclamped actuators to move and affect operator safety. They are designed specifically for Hytec’s No. 100969 and No. 100970 Directional Control Valves.

The 1⁄4 NPT (500172) and the SAE-4 (500174) “P” port check valves are required on all single acting or double acting circuits where there is more than one directional valve per power source. These check valves prevent power source pressure fluctuations from affecting the pressure in clamped circuits. Without this check valve, shifting the directional control valve in one circuit will cause a temporary loss of clamping pressure in the other circuit.

View Catalog - Check Valves - US

3-way/4-way, 2-position directional control valve. Ideal for manifold mounting.

Features

Similar to Hytec’s 100969 and 100970, this 3-way/4-way, two-position directional control valve is ideal for manifold mounting on your fixture. The valve’s zero-leakage design is the right choice for constant pressure applications. Its smaller size allows you to maximize usable fixture space.

This valve is designed with a standard ANSI, DO3 mounting and port configuration. The control lever can be placed in any of 24 positions without tools. Infinite adjustments are possible by loosening a locknut. Internal stops and detents along with a shaft wiper seal provide excellent contamination resistance.

Built without check valves, this valve is intended only for systems with one valve per hydraulic pressure source. For multiple valve applications, simply add the 100974 check valve sub-plate. Ported subplates 100972 and 100973 or manifold 100975 can also be added as appropriate.

- 3-way/4-way, 2-position, detented

- ANSI, DO3 mounting configuration

- Single or double acting systems

- Manually operated, 90 deg. swing

- 1500 psi max. return line pressure

- Optional SAE or NPT ported subplates

- Infinite handle adjustment

- 5,000 psi max.

- Shaft wiper excludes contaminants

- Optional check-valve subplate

View Catalog - Manifold Mounted Valves - US

Multiple-turn flow restrictor valves

Features

Hytec’s Needle Valves are multiple-turn flow restrictor valves which provide finely adjustable flow control for components or circuits requiring reduced flow rates. They are also used in some non-critical sequencing applications where restriction in part of a circuit will tend to cause the actuators in the remainder of the circuit to operate first. Needle valve No. 253605 restricts flow in both directions.

- Corrosion resistant construction

- 5,000 psi maximum

View Catalog - Needle Valves - US

Ideal for Pallet applications or other specialized control circuits.

Features

Hytec’s pilot operated check valve offers a unique poppet seal design making them ideal for pallet applications or other specialized control circuits where zero leakage is essential. They can be used in any application where pressure must be maintained in a portion of a circuit until a separate pilot signal opens the valve and allows free flow in the reverse direction.

The pilot pressure required to release the valves is approximately one third of the pressure being released. The pilot piston is sealed to prevent pilot flow through the valve.

These valves are used with Hytec’s Automatic Pallet Coupling System and double-acting manual pallet valve. The replaceable filter elements protect the check valve and your other system components from contamination. No disassembly of circuit plumbing is required to service the filters or the check valve cartridge. An additional filter is recommended for protection of the return side of double-acting clamping circuits.

- Replaceable, cartridge design valve

- Filters in all three ports protect the check valve and downstream components

- Filters are replaceable without disassembly of plumbing

- SAE O-rings ports

- 10 micron (25 micron absolute) filtration level

- Specially reinforced filter elements resist fatigue from pressure spikes

- 5,000 psi maximum

- No. 100915 replaces and directly interchanges with No. 100856

View Catalog - Pilot Valves - US

Designed to be used in applications where the pump is located near the operator with the valve mounted directly on the pump. This configuration eliminates the need for pressure and return lines between the pump and remote mounted control valves. It will replace the outlet manifold on most Hytec constant pressure pumps having that feature. (For use with Hytec No. 100178 pump, contact Hytec Technical Services.) One pump/valve combination is required for each circuit to be controlled.

Features:

- 3-way/4-way, 2-position, detented

- Manually operated

- Pump mounted

- Handle swings 90° and can be repositioned in 22.5° intervals

- Single- or double-acting systems

- 1⁄4” NPTF reducer bushing

- Includes mounting hardware, return tube

- 5,000 psi max.

- 5 gpm max

View Catalog - Pump Mounted Valves - US

Valves are adjustable: 1,000 to 5,000 psi

Features

Pressure reducing valves are designed to reduce the maximum pressure in a portion of a hydraulic circuit: the valve is open from the inlet to the outlet until a pre-selected pressure is reached, at which point the valve closes to limit pressure in the secondary circuit. The need for a separate power source for each pressure level is eliminated.

Valves seats and poppets are precision ground, assuring virtually zero leakage and eliminating the need for a case drain line. The drain port (T) is used only during set up of the internal safety relief valve. This adjustable relief valve can be set to just above the reduced pressure setting so it will open only if contamination or another malfunction prevents the pressure reducing valve from closing, causing the outlet pressure to rise above the relief valve setting. The drain port should never be plugged, although it is seldom permanently plumbed into the circuit.

- Valves are adjustable from 1,000 to 5,000 psi outlet pressure

- Internal check valve allows free flow in reverse direction

- Maximum flow rate at 5 gpm

- NPT, SAE or manifold mount

- Automatically reopens to replenish lost pressure

View Catalog - Reducing Valves - US

Remote Valves are ideal for mounting directly on the machine or fixture for maximum operator convenience. They also permit the pump to be located away from the operator’s workstation. Each of these valves allows several circuits to be controlled with a single pump.

View Catalog - Remote Mounted Valves

Adjustable Sequence pressure range: 0 to 4,000 psi.

Features

Sequence valves control the order of events within a hydraulic system by directing pressure to the two circuits in a pressure-controlled sequence. For example, this allows clamps to be actuated before work supports are locked.

Initially, the valve is closed. Oil flows to the primary circuit until pressure reaches the valve setting. The valve then opens to deliver oil to the secondary circuit while holding pressure on the primary circuit. Once secondary and primary pressures are equal, the pressure increases uniformly in both circuits. There is no reduction of pressure available to either circuit.

- Sequence pressure range is adjustable from 0 to 4,000 psi

- Usable with hydraulic systems operating up to 5,000 psi

- Will not reduce pressure to the secondary circuit

- Minimum operation pressure should be 120% of sequence pressure setting

- Internal check valve allows free flow in reverse direction

- Maximum flow rate 5 gpm

- Suitable for single- and double-acting circuits

- NPT, SAE or manifold mounting

View Catalog - Sequencing Valves - US

Single-station Sub-Plates (No. 100972 and 100973)

These D03 sub-plates are for use with the 100971 directional control valve and 100974 check valve sub-plate. These assemblies will provide conventionally ported, remote mounted, directional control valves for use in multiple valve systems. These sub-plates may also be used with the 100971 directional control valve only in single valve systems. (For single valve applications, consider using valves 100969 and 100970.) Optional mounting bracket (No. 500175) is available.

Two-Station Manifold (No. 100975)

This manifold provides for mounting two, 100971 directional control valves. External plumbing is reduced because both DO3 mounting patterns share the same pressure and tank ports. Check valve sub-plate 100974 must also be used in workholding circuits.

Check Valve Sub-Plate (No. 100974)

Use this in directional control valve in applications requiring inlet and outlet checks. (Ports P and T) When two or more valves are connected to the same pressure source, these check valves prevent pressure fluctuations in one system from affecting the other. Without this check valve sub-plate, the shifting of one valve in a system can cause the loss of clamping pressure in another. This check valve subplate uses the same DO3 mounting configuration as our 100971 directional control valve. It is simply placed underneath the valve. Mounting screws are included.

View Catalog - Control Valve Accessories - US