SWcip4 Series - Double Seal Valves

The SWcip4 valve is a double seal valve designed especially for CIP applications. The valve replaces old-fashioned block and bleed concepts based on three butterfly valves or double butterfly valves. With two serial seat seals and a separation cavity, this double seal valve ensures that intermixing of CIP media is avoided. This valve helps to increase product safety demands in CIP systems.

FEATURES

The SWcip4 series double seal valve is just right for isolation between your CIP media tank and the CIP supply and CIP return line. Built on the principles of the SW4 and SD4 valves.

Advantages

- Profile seals that eliminate gaps and ease ordering of spares due to ID-numbering

- Mix proof separation of CIP media

- Easy to maintain due to low weight, few seals and maintenance-free actuator

- Reduced maintenance costs due to the metallic stop and longer lasting seals

- Flexible design due to interchangeable actuators to handle different product pressures

How does a double seal valve work ?

The SWcip4 valve is used for the safe separation of CIP liquids at cross-over points of piping in CIP stations.

Separation is provided by two seat seals. A leakage chamber which is forcibly closed by a leakage valve or open to the atmosphere is located between the seals. Leakage at the seat seals is indicated and discharged to the atmosphere by the leakage valve.

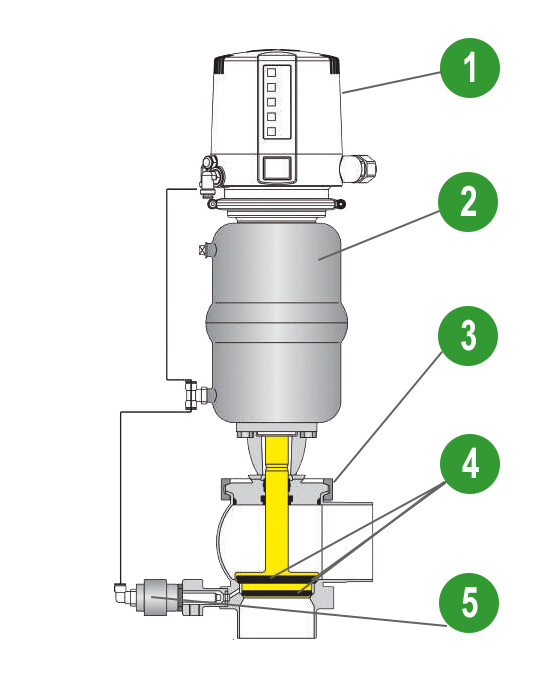

Callouts:

- Control unit

- Pneumatic actuator

- Clamp closure

- Seat seals

- Leakage discharge valve

DIMENSIONS & SPECIFICATIONS

SWcip4 Series Double Seal Valve Dimensions

view swcip4 series double seal valve dimensions in the operation and instruction manual