LeanCreme™ - Microparticulation of whey proteins

Dairy based ingredient for optimizing yields and value.

FEATURES

Patented SPX FLOW LeanCreme™ technology produces LeanCreme microparticulated whey protein concentrate. This dairy based functional ingredient can improve the value of products including cheese, milk desserts, protein enriched drinks, dressings and sauces, ice cream, confectionary, bakery products, nutraceuticals, powder ingredients and meat production. Benefits include:

- Replacing fat

- Dairy based stabilizer

- Improving mouthfeel

- Increasing nutritional value

- Increasing cheese yields

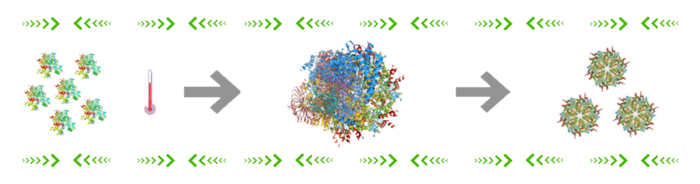

Microparticulation of whey proteins

Heat denaturation

Aggregation and controlled mechanical shear

By combining the thermal and mechanical treatment of the whey protein concentrate (WPC), the process enables accurate control of heat and shear force to produce consistent and ideal particle sizes during the denaturation process– providing adequate functionality and sensorial properties to the end product (e.g. similar to fat globules in milk) with a reduced fat content.

- Cheese:

- LeanCreme™ microparticles can be sized to emulate fat globules and improve mouth feel in low fat products.

- Recovering whey protein from the cheese whey and returning it to the cheese milk in the form of LeanCreme microparticles will increase overall cheese yield per kg of milk.

- Ice cream: LeanCreme microparticulated whey protein concentrate can act as a natural, dairy based stabilizer for clean label products

- Nutritional beverages: LeanCreme microparticles can increase nutritional product value without compromising the desirable product characteristics such as texture and mouthfeel