STORIES IN THE MAKING

Not All Drywells Are Created Equal: True Protection

In mixing applications where contamination and safety aren’t optional—they’re essential—selecting the right drive system isn’t just smart, it’s mission-critical. And at the center of that decision is one component that’s often misunderstood, misrepresented, or entirely missing: the drywell.

What is a True Drywell—And Why It Matters

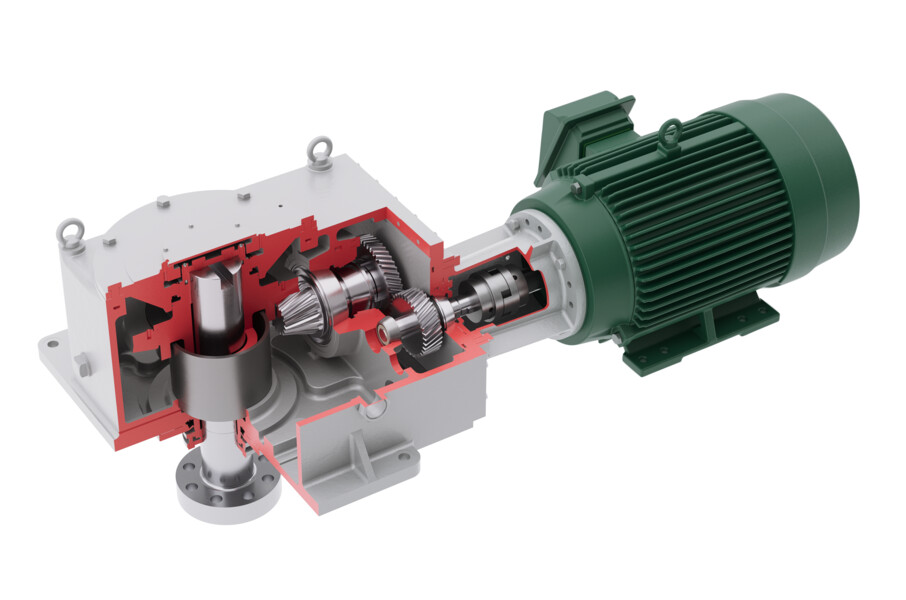

At its core, a true drywell is a non-contacting, stationary barrier that separates the gearbox’s lubricating oil from the output shaft and the process zone. Its function is straightforward: to prevent oil migration that can compromise product purity, create safety hazards, and increase maintenance.

Lesser designs, like lip seals, double lip seals, or oil slingers, rely on contact-based sealing methods that wear over time. True drywells, on the other hand, are built into the gearbox casting and require no maintenance or replacement to remain effective.

Why the True Drywell Is the Only Right Choice

A true drywell does more than prevent lubricant contamination. It:

- Protects the Process – Ensures zero oil intrusion into your product

- Protects People – Avoids oil leaks on production floors that cause slips, trips, and injuries

- Protects the Gearbox – Prevents bearing failure due to oil washout

- Protects the Business – Reduces downtime, regulatory risk, and warranty issues

- Reduces Maintenance – Frees up time to focus on more critical needs

Industries That Can’t Afford to Compromise

- Pharmaceuticals – Where cleanliness and sterility are mandated

- Food & Beverage – Where consumer safety is non-negotiable

- Chemicals & Coatings – Where contamination can destroy entire batches

- Water Treatment – Where leaks cause compliance and environmental issues

SPX FLOW Mixer Drives with Built-In True Drywells

SPX FLOW Mixing Solutions integrates true drywells into select gearboxes across our Lightnin and Philadelphia product lines, including:

- Lightnin - Series 10 – Medium Torque Top Entry Mixer

- Lightnin - 70 Series - Medium Torque Top Entry Mixer

- Lightnin - 80 Series - Medium Torque Top Entering Mixer

- Lightnin - Compact Series – Medium Torque Top Entering Mixer

- Lightnin - 980 Series – High-Torque Top Entry Mixer

- Lightnin - 700/800 Series High Torque Top Entry Mixer

- Philadelphia - Raven 3800 Series Mixer Drive

These AGMA-rated, mixer-specific drives are purpose-built to handle high bending moments, overhung loads, and long shafts, while maintaining absolute isolation between lubricant and process.

The misrepresentation of lesser technologies to circumvent a true drywell is becoming more commonplace, causing undesirable outcomes for the user.

That’s why we emphasize clarity in both specification and communication. The wrong gearbox might work, for a while. But in critical mixing applications, "good enough" simply isn’t.

When Purity, Safety, and Reliability Matter Most, Specify a True Drywell

Let’s not leave this to chance. If you’re unsure whether your drive includes a true drywell, or want help with specification language, our team is here to guide you.

Talk to our experts at SPX FLOW Mixing Solutions to specify the right gearbox for your application, engineered with true drywell protection, from the start.

Frequently Asked Questions