Driving Innovation in the Horticulture Industry

The horticulture industry is experiencing dynamic shifts in response to environmental challenges, regulatory demands and the need for efficient production practices. SPX FLOW, a leading innovator in fluid management, climate control and advanced mixing solutions, is uniquely positioned to support the horticulture sector’s objectives of increased productivity and sustainability. Our advanced centrifugal pumps, like the Johnson Pump® CombiLine and CombiBlocHorti, deliver unparalleled performance in managing greenhouse environments and optimizing irrigation.

With SPX FLOW, horticulture businesses gain access to an innovation center focused on automation, digitalization and resource efficiency, + which are essential for modern-day horticulture. Our products are meticulously designed for energy efficiency and operational reliability, supporting site managers, senior operations engineers and plant managers in driving both sustainability and cost-effectiveness across their facilities.

SPX FLOW’s commitment to the horticulture industry is reflected in our comprehensive service offerings and lifecycle cost management. By choosing SPX FLOW, horticulture leaders can trust in solutions that reduce maintenance needs, extend equipment longevity and promote safer, more sustainable operations.

Advanced Pump Technologies

-

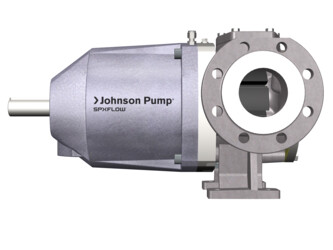

Johnson Pump CombiLine – Centrifugal Pump with In-line Ports:

Engineered for reliability and efficiency, the CombiLine pump supports critical fluid management processes within greenhouses. Its in-line ports facilitate seamless integration with various irrigation systems and climate control setups.Learn more

-

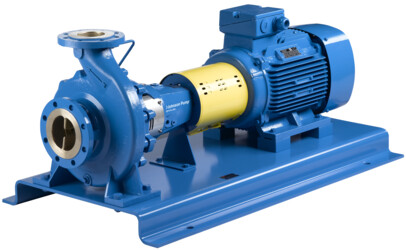

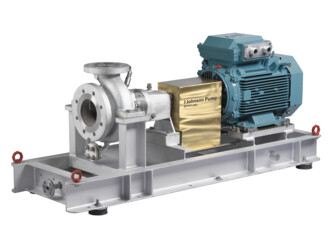

Johnson Pump CombiBlocHorti – Close-Coupled Centrifugal Pump:

Tailored for horticulture needs, the CombiBlocHorti pump excels in high-flow applications, ensuring consistent fluid delivery across large greenhouse spaces. Learn more.

Our pumps are proudly manufactured in Assen, Netherlands, located at the center of Europe’s horticulture innovation region, connecting our products to the forefront of industry advancements. Trusted across the horticulture sector, these pumps support sustainable practices, drive energy efficiency and enhance greenhouse operations.

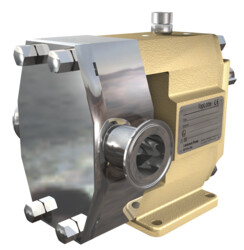

Advanced Mixing Technologies

SPX FLOW also offers cutting-edge mixing solutions that support various stages of horticultural production, from fertilizer formulation to pesticide and fungicide safety. Our advanced mixers are engineered for the complex requirements of ingredient extraction, purification and conversion processes that meet both horticultural and regulatory standards. Key features of our mixing technologies include:

-

Fertilizer Manufacturing:

SPX FLOW's mixing solutions support every stage of the fertilizer production process, from extracting targeted ingredients to producing high-quality, intermediate or finished fertilizer products. Our agitators in beneficiary plants purify and qualify mined ingredients, while our reactor-based agitators reduce unplanned downtime, increasing annual production days. Additionally, our mixers extend the operational time between plant turnarounds and cleanouts, making them ideal for storage tanks and other high-use facilities.

-

Fungicide and Pesticide Production:

Safety and reliability are paramount when manufacturing fungicides and pesticides, given the hazardous nature of these chemicals in concentrated form. SPX FLOW’s proven agitation equipment minimizes the risks associated with producing these volatile substances, ensuring safe handling and consistent results. Our equipment’s robust design reduces the risk of leaks or accidental releases from pressurized tanks, offering peace of mind and operational reliability.

By enabling even nutrient distribution, optimizing ingredient consistency and promoting effective growth support, SPX FLOW’s mixing solutions help horticulture operators increase both crop yield and soil conservation efforts. Our solutions are also designed to support sustainability through minimized environmental impact and maximized resource efficiency.

Why Choose SPX FLOW?

SPX FLOW differentiates itself through a commitment to horticulture-specific innovations that improve efficiency, safety and cost-effectiveness. By investing in our technology, horticulture professionals benefit from:

-

Genuine Spare Parts and Service:

Ensuring optimal performance and extending the equipment lifecycle.

-

Sustainability and Efficiency:

Our products are designed to minimize environmental impact and reduce resource consumption.

-

Reliability and Safety:

Engineered to meet the rigorous demands of the horticulture industry, our solutions promote operational safety and consistent performance.

Call to Action:

Experience SPX FLOW’s commitment to horticulture. Contact us today to learn how we can help you achieve greater sustainability and productivity in your operations.