Heat Exchangers Tailored for Food, Beverage & Industrial Markets

SPX FLOW offers cutting-edge heat exchangers tailored to meet the unique needs of the food, beverage and industrial markets. Designed to deliver exceptional efficiency and maintain strict hygiene standards, SPX FLOW heat exchangers are purpose-built for applications that demand reliability and performance. With a versatile portfolio of plate heat exchangers, scraped surface heat exchangers and tubular heat exchangers SPX FLOW ensures the right solution for every operation, whether you’re focused on product integrity in food processing or durability in harsh industrial settings.

Plate Heat Exchangers

Plate heat exchangers are ideal for applications requiring compactness and high thermal efficiency. Their scalable design allows for easy expansion and maintenance, making them a preferred choice in a wide range of heat transfer scenarios. As the inventors of the plate heat exchanger, we have set the standard for innovation and performance in heat transfer technology.

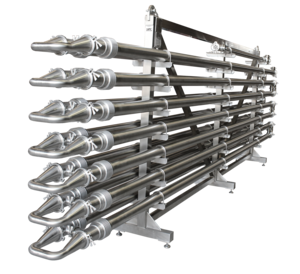

Tubular Heat Exchangers

Tubular heat exchangers are designed to provide durability and reliability in applications involving products with varying viscosities, including those containing particles and fibers. Our technology ensures efficient and uniform heat transfer, tailored to the specific requirements of each process.

The robust construction of our equipment enables operation under high-pressure and high-temperature conditions, ensuring optimal performance and an extended service life. This versatility makes our heat exchangers a trusted solution for industries such as food and beverage, chemical processing, pharmaceuticals, and wastewater treatment.

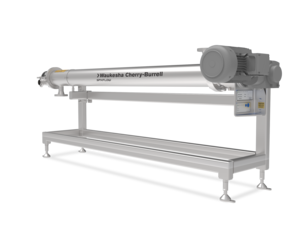

Scraped Surface Heat Exchangers

Scraped surface heat exchangers excel in handling high-viscosity products or applications with larger particle sizes. This type is essential in applications where preventing product buildup on the heat transfer surface is critical, offering superior product quality in applications like meat processing and peanut butter.

SPX FLOW: Trusted by Industry Leaders for Heat Exchange Solutions

SPX FLOW brings decades of experience to the heat exchanger market, setting industry standards for quality, efficiency and reliability. Our heat exchangers are engineered with flexibility in mind, allowing them to adapt to various product viscosities, flow rates and temperature ranges. By choosing SPX FLOW, you gain access to a team of experts who understand the unique challenges of your industry and can provide solutions to help optimize your processes.

-

Sanitary Excellence:

SPX FLOW’s heat exchangers meet stringent sanitary requirements, making them ideal for sanitary applications in food and beverage processing.

-

Engineered for Durability:

Our industrial heat exchangers withstand extreme environments, maintaining performance in high-stress applications within chemical processing, oil and gas, mining, and other industrial markets.

-

Energy Efficiency:

Designed to reduce energy costs, SPX FLOW heat exchangers offer high thermal efficiency and optimal heat transfer, supporting both operational savings and sustainability goals.

Why Choose SPX FLOW?

SPX FLOW stands out by delivering tailored heat exchanger solutions that meet the rigorous demands of both sanitary and industrial applications. Our commitment to quality and innovation means you’ll receive a solution engineered to optimize productivity, ensure product quality and lower operational costs. Our heat exchangers are more than equipment; they’re an investment in your operation’s success.

Contact SPX FLOW today to learn more or request a consultation.