High-Performance Centrifugal Pumps for Food, Beverage and Industrial Applications

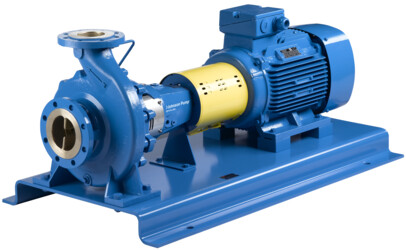

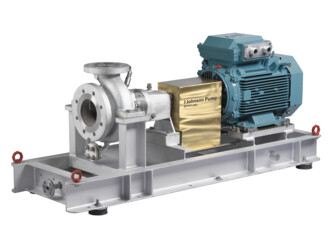

Centrifugal pumps are the backbone of fluid transfer in food, beverage and industrial applications, offering unmatched reliability and smooth operation for a wide range of low-viscosity liquids. These pumps are designed to handle high-volume fluid movement, making them essential in processing environments where quality and efficiency are paramount.

SPX FLOW specializes in centrifugal pumps that cater to the specific needs of industries like food and beverage, chemical processing, and water treatment. Our pumps deliver dependable performance and are engineered to comply with industry standards, ensuring seamless integration into your production processes. Whether you’re managing delicate food ingredients or complex chemical solutions, SPX FLOW’s centrifugal pumps offer robust, reliable and efficient solutions that adapt to your specific application requirements.

Why Choose SPX FLOW for Centrifugal Pumps?

Choosing SPX FLOW means choosing a partner dedicated to engineering excellence, quality and performance. Our centrifugal pumps are tailored to meet the rigorous demands of food, beverage and industrial sectors, making SPX FLOW an industry leader for fluid handling solutions.

- Precision Engineering: Our pumps are crafted with advanced design features that optimize flow rates and minimize energy consumption, ensuring peak efficiency.

- Durable and Reliable: Constructed with high-grade materials, SPX FLOW pumps are built to withstand challenging industrial environments and extended usage.

- Enhanced Productivity: Our pumps are designed to reduce operational downtime and increase productivity.

Ready to Optimize Your Process?

Contact us today to see how SPX FLOW centrifugal pumps can enhance your production efficiency and provide reliable performance.

A centrifugal pump creates pressure by converting rotational energy from an impeller into velocity (kinetic energy), which is then transformed into pressure energy to move fluid. It is ideal for transferring low-viscosity fluids efficiently and reliably.

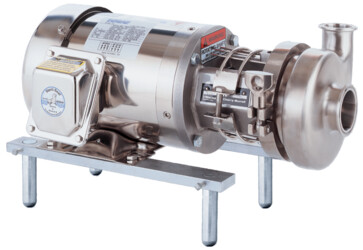

What are the benefits of centrifugal pumps in food and beverage applications? Centrifugal pumps are a cost-effective, compact and mechanically simple solution for transferring low-viscosity liquids. Their robust design supports easy maintenance and ensures process integrity, making them a reliable choice for meeting food and beverage standards.

Routine inspections and part replacements, such as seals, are recommended to ensure optimal performance. SPX FLOW’s centrifugal pumps feature a close-coupled design, simplifying maintenance and reducing complexity. Additionally, SPX FLOW provides comprehensive maintenance support and guidelines to maximize pump longevity.

These pumps are best suited for low-viscosity fluids. For high-viscosity applications, positive displacement pumps are generally recommended.

These pumps operate efficiently when specified correctly. Our channel partners and application engineers can work with you to select the right pump for your application and optimize it for a range of operating conditions.

SPX FLOW’s centrifugal pumps are made from high-quality, corrosion-resistant materials, such as stainless steel, for durability and compliance with industry standards. SPX FLOW’s centrifugal pumps are primarily constructed from high-quality 316 stainless steel, ensuring durability and corrosion resistance in demanding environments. We also offer options in Alloy 88, a nickel-based, FDA-approved material that prevents galling and seizing, allowing for tighter clearances and higher efficiency. Additionally, for applications involving highly acidic products, we provide AL6XN, a super-austenitic stainless steel that offers superior resistance to corrosion, further enhancing the pump's performance and longevity.

SPX FLOW offers a range of centrifugal pump designs to meet various sanitary and industrial requirements. Open and semi-open impeller designs are ideal for handling fluids with suspended solids. Close-coupled and pedestal mount configurations provide flexibility in installation and maintenance. The high-efficiency W+ Series delivers optimal performance in demanding applications, while the robust 200 Series is built for heavy-duty use where durability is essential. For more budget-conscious needs, the value-optimized C-Series offers reliable performance at a lower cost. These options include both sanitary models suited for food and beverage processing as well as industrial-grade pumps designed for broader application needs.

Yes, they are designed for straightforward installation, and our team offers support to ensure seamless integration into your system.

SPX FLOW offers comprehensive support, including installation guidance, maintenance training and a dedicated customer service team. SPX FLOW also hosts factory-led training schools which cover pump fundamentals and hands-on repair training.